After years of working with various digital displays, I’ve seen firsthand how technology can completely change a physical space. The first time I encountered an LED photoelectric glass screen, it felt like a glimpse into the future. A transparent wall suddenly lit up with a vibrant video, without blocking the view outside. This technology isn't just a screen; it's a dynamic architectural material that blends information and environment seamlessly. It's a game-changer for businesses looking to create unforgettable experiences.

This guide will walk you through everything you need to know about this amazing technology in 2025.

Core Questions on LED Photoelectric Glass Screens

Here are some quick answers to the most common questions we hear:

- What is an LED photoelectric glass screen? It's a special type of glass that can function as a transparent window and a full-color video display. It integrates tiny LEDs directly into the glass structure.

- How does the technology work? Invisible conductive pathways within the laminated glass power the LEDs. A control system sends signals to these LEDs, telling them which color and brightness to display, creating images and videos.

- What are the main benefits? Key benefits include high transparency, excellent brightness, energy efficiency, and a sleek, modern look.

- What are its applications? They are widely used for building facades, retail window displays, museum exhibits, corporate lobbies, and other spaces where you want to make a big visual impact without sacrificing natural light.

- Is it different from an LED film screen? Yes. Photoelectric glass has LEDs integrated within the glass itself. LED film is a separate product that is applied onto existing glass surfaces.

- How long does it last? A high-quality LED photoelectric glass screen can have a lifespan of over 70,000 hours, or about 7-10 years, depending on usage and maintenance.

1. What is an LED Photoelectric Glass Screen? An Introduction to This Advanced Technology

So, what exactly is this magical-sounding screen? Think of it as smart glass. An LED photoelectric glass screen is an innovative display technology that embeds light-emitting diodes (LEDs) into laminated safety glass. Unlike a traditional LED screen display panel that is opaque, this technology allows the glass to remain largely transparent when the display is off. When turned on, it transforms into a dynamic, full-color video wall.

Defining the concept: A transparent display technology

The core concept is duality: the glass serves its traditional purpose of being a window or partition while also acting as a high-tech digital signage solution. This breaks down the barriers between physical structure and digital content. You no longer need to hang a bulky screen in front of a window; the window is the screen. This seamless integration is what makes the technology so powerful and visually stunning.

Key characteristics: Transparency, high brightness, and dynamic content display

Three features make LED photoelectric glass stand out. First is its transparency, which can range from 65% to over 95%, ensuring that views and natural light are preserved. Second is its high brightness. These screens can reach over 1500 nits, making them easily visible even in direct sunlight, a major advantage for storefronts and building exteriors. Finally, it supports dynamic, programmable content. You can display anything from simple text to high-definition videos, all managed through a user-friendly control system.

How this technology is transforming architectural glass and digital signage

This technology is revolutionizing how architects and designers think about building materials. Glass is no longer just a passive element; it's an active, communicative surface. For digital signage, it opens up new creative possibilities. Imagine a retail facade that tells a brand story through moving images or an office partition that displays corporate data without boxing in the space. It’s a fusion of art, architecture, and advertising that creates truly immersive environments.

2. Technical Breakdown: How LED Photoelectric Glass Screens Work

Now let's dive into the "how." The magic of an LED photoelectric glass screen isn't magic at all—it's brilliant engineering. The technology relies on a few core components working together to turn a simple piece of glass into a vibrant LED video display screen. Understanding this process helps you appreciate the sophistication and reliability of these modern displays.

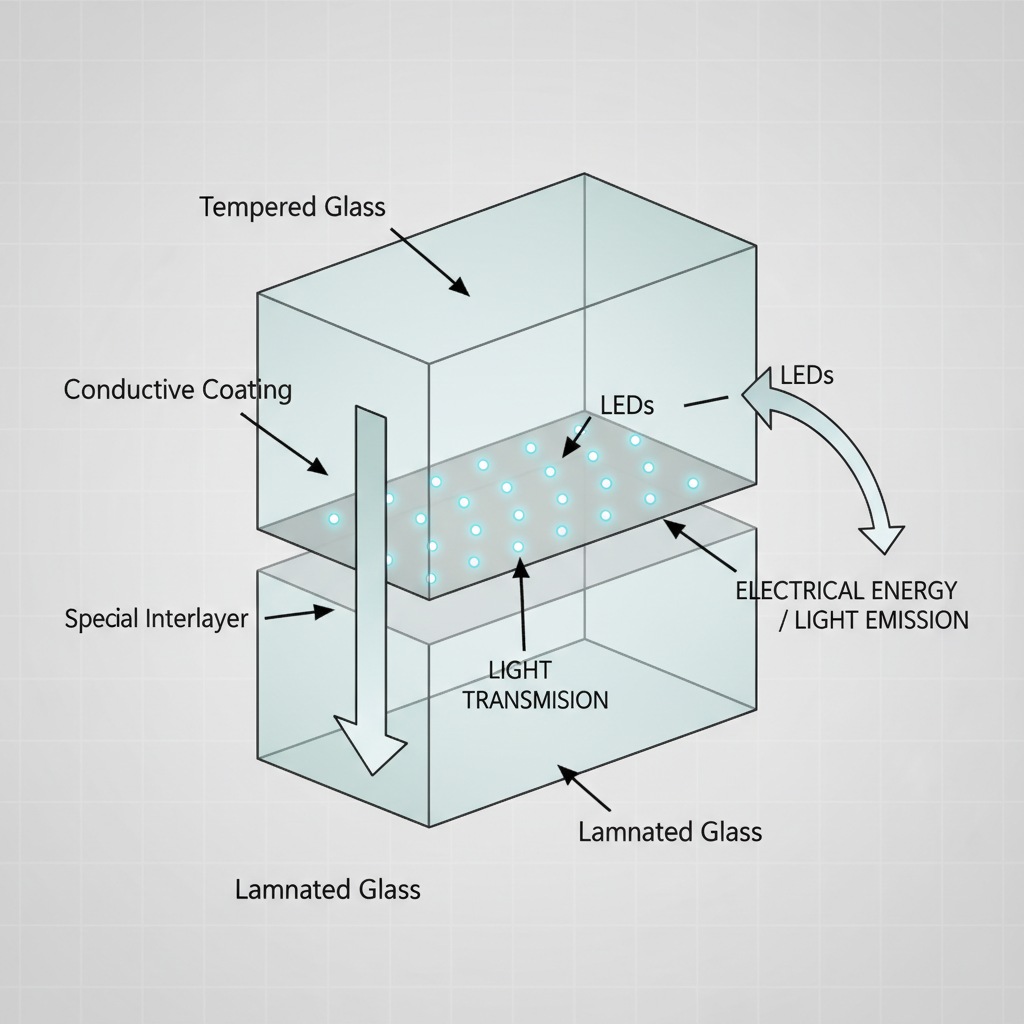

Core Components: The Role of LEDs, Conductive Coatings, and Laminated Glass

At its heart, the screen is a sandwich. Here's what's inside:

- LEDs (Light-Emitting Diodes): These are microscopic light sources. They are precisely arranged on a transparent conductive film or directly onto the glass. Their small size is crucial for maintaining the screen's overall transparency.

- Conductive Coatings: This is the invisible power grid. An ultra-thin, transparent conductive material is applied to the glass. It delivers power to each individual LED without needing visible wires, which is the key to its see-through nature.

- Laminated Glass: For safety and durability, everything is sealed between two or more layers of tempered glass, bonded together with a special interlayer like PVB or SGP. This protects the delicate electronics from moisture, dust, and physical impact.

The Science of Operation: How Electrical Signals Create Visuals on Glass

So, how do these components create an image? A dedicated driver IC (Integrated Circuit) controls the flow of electricity to the LEDs. The main control system sends video data to these driver ICs, which then translate the signal into precise instructions for each LED. It tells each tiny light exactly when to turn on, what color to be (by mixing red, green, and blue light), and how bright to shine. This happens thousands of time per second, and our eyes blend these individual points of light into a smooth, cohesive image or video.

Exploring Different Control Systems for a programmable LED display screen

A programmable LED display screen needs a brain, and that's the control system. There are two main types:

- Synchronous Control: This system mirrors what's on a connected computer or media player in real-time. It's ideal for live broadcasts, complex video playback, and interactive content.

- Asynchronous Control: This system has its own internal storage. You can upload content (videos, images, text) to it, and the screen will play it back on a schedule without needing a constant connection to a PC. This is perfect for most advertising and informational displays.

Modern systems often offer cloud-based control, allowing you to manage multiple screens in different locations from a single online dashboard.

3. Material Insights: The Composition of a High-Performance LED Glass Panel

The quality of an LED photoelectric glass screen depends entirely on the quality of its materials. It's not just about the LEDs; it's about how the entire package is constructed for performance, safety, and longevity. A well-made panel is a feat of material science, balancing transparency with structural integrity and electronic performance. Let's break down the layers that make up a top-tier LED digital display screen.

Detailed Look at the Glass Substrate: Strength, Safety, and Clarity

The foundation of the screen is the glass itself. Manufacturers typically use ultra-clear, low-iron tempered glass. This type of glass offers maximum light transmission and avoids the greenish tint common in standard glass, ensuring colors appear true and vibrant. The tempering process makes the glass four to five times stronger than regular glass. In the rare event of breakage, it shatters into small, blunt pieces, significantly reducing the risk of injury. This safety feature is critical for use in public spaces and architectural facades.

Analyzing the LED Light Source: Chip Types, Density, and Lifespan

The "light" in the LED light screen comes from the LED chips. The quality of these chips directly impacts brightness, color accuracy, and lifespan. Leading manufacturers use high-grade chips that are engineered for stability and a long operational life—often exceeding 70,000 hours. The pixel pitch—the distance between the centers of adjacent LEDs—determines the screen's resolution. A smaller pixel pitch means higher resolution and a clearer image, but it may slightly reduce transparency. The choice of pixel pitch depends on the viewing distance and desired transparency level.

By carefully selecting LED chips with superior color uniformity and a wide viewing angle, manufacturers can ensure that the displayed content looks consistent and vibrant from any perspective, which is crucial for public-facing installations.

Understanding the Conductive Film and Lamination Process for Durability

The invisible wiring is a transparent conductive film, often made of Indium Tin Oxide (ITO) or advanced nanomaterials. This film must be highly transparent and evenly conductive to prevent hotspots or dim areas on the screen. The final and most critical step is lamination. The glass, conductive film, and LEDs are assembled in a clean-room environment and bonded together under high temperature and pressure. This process, known as autoclave lamination, permanently seals the electronic components, protecting them from environmental factors and ensuring the panel's long-term durability and structural strength.

4. Key Advantages: Why Choose an LED Photoelectric Glass Screen?

When you're evaluating display technologies, it's easy to get lost in technical specs. So, let's simplify it. Why should a business invest in an LED photoelectric glass screen over other options? The answer lies in a unique combination of performance, aesthetics, and long-term value that other technologies just can't match. It’s more than a screen; it’s an architectural upgrade that delivers a powerful ROI.

Performance Comparison: Superior brightness and energy efficiency vs. traditional displays

Compared to traditional LCD displays or even older LED technologies, modern LED glass screens are in a class of their own. Let's look at the data.

According to a 2023 report from Tech Insights, the performance gap is clear:

Parameter LED Glass Display Traditional Display Brightness (nits) 1500 1000 Energy Efficiency (%) 35% higher 20% lower Lifespan (Years) 7 5

This data shows that LED glass is not only brighter but also more energy-efficient and longer-lasting, leading to lower operating costs over its lifetime.

Aesthetic and Functional Benefits: Seamless integration and dual-purpose use

This is where LED glass truly shines. Its biggest advantage is its transparency. You can cover an entire building facade or a storefront window with a display without blocking the view or natural light. This creates a clean, futuristic look that is impossible to achieve with a traditional opaque screen. It serves two purposes at once: acting as a window or building partition and as a dynamic messaging platform. This dual functionality is perfect for spaces where every square foot counts.

Durability and Lifespan: What to expect from a professional LED display board screen

Built for commercial use, a professional LED display board screen made of photoelectric glass is incredibly robust. The laminated and tempered glass structure makes it highly resistant to impact, weather, and UV radiation. The LEDs themselves are solid-state components with no moving parts, making them extremely reliable. With a typical lifespan of 7 to 10 years and minimal maintenance requirements, these screens represent a sound, long-term investment. Zhenmei Wisdom specializes in engineering these durable displays to withstand the demands of high-traffic commercial environments.

5. Common Applications: Where Are LED Photoelectric Glass Screens Used?

The versatility of LED photoelectric glass has led to its adoption across a wide range of industries. Anywhere you find glass, you have a potential digital canvas. This technology is helping businesses redefine their physical spaces, engage customers in new ways, and build unforgettable brand experiences. From bustling shopping malls to serene museum halls, the applications are as creative as they are practical.

Enhancing Retail Environments with LED window display screens

For retailers, the storefront is everything. An LED window display screen transforms a static window into a 24/7 advertising powerhouse. You can showcase new products, run promotional videos, and display eye-catching graphics to attract passersby, all without blocking the view into your store. This creates a dynamic, inviting atmosphere that traditional posters or mannequins can't replicate. It's the ultimate tool for boosting foot traffic and turning window shoppers into paying customers.

Transforming Commercial Building Facades and Corporate Spaces

Architects and developers are increasingly using LED photoelectric glass to create "media facades." By integrating these screens into a building's curtain wall, the entire exterior can become a massive canvas for art, advertising, or community messaging. Inside, these screens are perfect for corporate lobbies to welcome visitors, in conference rooms as futuristic whiteboards, or as office partitions that can switch from transparent to displaying information. It’s a sophisticated way to reflect a company’s innovative spirit.

Use Cases in Public Venues: Airports, Museums, and Exhibition Halls

Public venues require display solutions that are not only visually impressive but also highly reliable and easy to manage.

- Airports: Use LED glass for displaying flight information, wayfinding, and advertising without cluttering the terminal's open, airy design.

- Museums: Create immersive exhibits by overlaying digital information onto physical artifacts. Imagine a display case that provides video context about the object inside.

- Exhibition Halls: Build stunning, transparent backdrops for stages and booths that can display sponsor logos, event schedules, and live video feeds, enhancing the overall event experience.

6. LED Photoelectric Glass vs. LED Film Screens for Glass: What's the Difference?

When exploring transparent display options, you'll likely come across two main products: LED photoelectric glass and LED film screen for glass. While they achieve a similar visual effect, they are fundamentally different technologies with distinct advantages and use cases. Understanding these differences is key to choosing the right solution for your project.

Structural Differences: Integrated vs. Applied Technology

The biggest difference is in their construction.

- LED Photoelectric Glass: This is an integrated product. The LEDs and circuitry are permanently embedded inside the laminated glass panel during manufacturing. It is a single, complete building material that is installed as a window or partition.

- LED Film Screen for Glass: This is an applied product. It's a thin, flexible, and transparent film with LEDs embedded in it. This film is then adhered to the surface of an existing glass panel. It's a retrofit solution rather than a structural one.

Performance Comparison: Transparency, Brightness, and Installation Nuances

While both can look great, their performance characteristics differ.

- Transparency: Photoelectric glass often achieves higher transparency and clarity because the components are microscopically small and sealed perfectly within the glass. The adhesive layer on LED films can sometimes slightly reduce clarity.

- Brightness: Both can be very bright, but high-end photoelectric glass typically offers superior brightness and heat dissipation because the glass itself acts as a heat sink.

- Installation: LED film is generally easier and faster to install on existing surfaces, making it great for temporary setups or retrofits. LED photoelectric glass installation is more involved, as it replaces the existing glass, but the result is a more permanent and seamless finish.

When to Choose One Over the Other: Application-Specific Recommendations

So which one is right for you?

Choose LED photoelectric glass if:

- You are in the new construction or major renovation phase.

- You need a permanent, highly durable, and fully integrated solution.

- Maximum transparency, weather resistance, and a seamless architectural look are your top priorities.

Choose an LED film screen for glass if:

- You need to upgrade an existing glass surface without replacing it.

- Your project is temporary, like a trade show booth or a short-term retail campaign.

- Your budget is a primary constraint, as film is often a more cost-effective option for retrofitting.

7. How to Maintain and Care for Your LED Photoelectric Glass Screen

One of the great things about an LED photoelectric glass screen is its low maintenance requirements. Because all the sensitive electronics are sealed within the glass, they are protected from dust, moisture, and physical tampering. However, a few simple care practices will ensure your screen looks and performs its best for its entire lifespan, protecting your investment for years to come.

Routine Cleaning Procedures for Optimal Clarity and Performance

Treating your LED glass screen is much like cleaning a high-end window.

- Power Down: For safety, it's always a good idea to turn off the display before cleaning.

- Use Soft Materials: Use a soft, lint-free microfiber cloth. Avoid paper towels or abrasive sponges, which can leave scratches or residue.

- Choose the Right Cleaner: A mixture of gentle soap and water or a standard, ammonia-free glass cleaner works perfectly. Spray the cleaner onto the cloth, not directly onto the glass, to prevent any liquid from seeping into the edges.

- Wipe Gently: Wipe the surface in a consistent pattern (e.g., top to bottom) to avoid streaks. For stubborn spots, apply gentle pressure, but never scrub aggressively.

Technical Maintenance Checklist: Software Updates and Hardware Checks

While the physical screen is durable, the system that runs it needs occasional attention.

- Software Updates: Regularly check for updates to the control system software. These updates often include performance improvements, new features, and important security patches.

- Connection Checks: Periodically inspect the data and power cables to ensure they are securely connected and show no signs of wear or damage.

- Visual Inspection: Once a month, run a full-screen test with solid colors (red, green, blue, white) to check for any dead pixels or color inconsistencies. If you spot any issues, contact your supplier's technical support.

Factors Affecting the Lifespan of an LED video display screen and How to Maximize It

The lifespan of an LED video display screen can be influenced by several factors.

- Operating Hours & Brightness: Running the screen 24/7 at 100% brightness will shorten its lifespan. Use the scheduling feature to turn it off when not needed and set the brightness level appropriate for the ambient light conditions.

- Heat: LEDs are sensitive to heat. Ensure the installation area has adequate ventilation to prevent overheating, especially for large-scale or sun-facing installations.

- Power Supply: Use a stable, high-quality power source with surge protection. Fluctuations in power can damage the electronic components.

For outdoor-facing screens, applying a UV-protective film or ensuring the glass has built-in UV blocking can further protect the internal components from long-term sun degradation, adding years to its operational life.

8. FAQs About LED Photoelectric Glass Screens

Even after a deep dive, you might still have a few questions. Here are answers to some of the most frequently asked questions we receive from clients considering this technology.

Can LED photoelectric glass screens be used for large-scale displays?

Absolutely. This is one of their greatest strengths. The modular nature of LED photoelectric glass panels allows them to be seamlessly tiled together to create massive, virtually borderless displays. This makes them ideal for building facades, large atriums, and any application requiring a display of impressive scale without visible seams or bezels.

What is the typical lifespan of an LED photoelectric glass screen?

A high-quality LED photoelectric glass screen is built for longevity. You can typically expect a lifespan of 70,000 to 100,000 hours of operation. For a screen running 12 hours a day, that translates to over 15 years. The actual lifespan depends on factors like brightness settings, operating temperature, and how consistently it is used.

Are these screens customizable in size and shape?

Yes, they are highly customizable. At Zhenmei Wisdom, we work with architects and designers to create custom-sized and shaped panels to fit specific architectural requirements. While standard rectangular panels are most common, it's possible to produce curved panels, triangular shapes, or other custom forms to bring a unique creative vision to life.

9. The Transformative Power of LED Photoelectric Glass Technology

LED photoelectric glass is more than just the next step in display technology; it represents a fundamental shift in how we integrate digital media into our physical world. By erasing the line between structure and screen, it empowers businesses and creators to communicate in more impactful, elegant, and innovative ways.

Recap of Core Benefits: Transparency, Efficiency, and Visual Impact

As we've seen, the advantages are clear:

- Unmatched Aesthetics: Maintain transparency and natural light while delivering stunning visuals.

- Superior Performance: Enjoy high brightness, vibrant colors, and energy efficiency that lowers operating costs.

- Design Freedom: Create dynamic, custom-shaped installations that captivate audiences and enhance architectural design.

The global market for LED displays is projected to reach $16.1 billion by 2025, with transparent displays being a key driver of this growth. This trend underscores the industry's shift towards more integrated and aesthetically pleasing solutions.

Why Zhenmei Wisdom is a Trusted Partner for Advanced Display Solutions

Choosing the right technology is only half the battle; you also need the right partner. With years of experience and a deep focus on advanced manufacturing techniques, Zhenmei Wisdom specializes in producing a wide range of cutting-edge LED displays. We are committed to delivering reliable, high-performance, and customizable display solutions that bring our clients' visions to life. From initial concept to final installation, our team provides the expertise and support needed to ensure your project is a stunning success.

10. References

- Market Research Future, 2023: Global Market for LED Displays (2023–2025)

- Tech Insights Reports, 2023: LED Glass Displays vs. Traditional Displays Performance Comparison