An engineering-led buyer’s guide to transparent LED film in 2025, explaining how brightness, transparency and pixel pitch interact, and how architects, integrators and procurement can specify the right balance for real projects.

I often meet project teams standing in front of a glass façade or flagship shop window, holding three very different quotations for “transparent LED film” that all look similar on paper but feel wildly different when powered on. Under pressure from brands, landlords and city regulations, you’re expected to turn that glass into media without killing daylight, breaking the façade rhythm or blowing the energy budget; yet spec sheets keep throwing “4000 nits, 70% transparency, P10” at you as if those numbers were self‑explanatory. The real questions I hear are always the same: how bright is “bright enough” in real sunlight, how much transparency can we sacrifice before tenants complain, and what pixel pitch actually works at 8 m or 25 m viewing distance? Let’s answer those concretely so you can read a datasheet and immediately know which transparent LED film configuration fits your project instead of guessing.

How to Specify Transparent LED Film in 30 Seconds

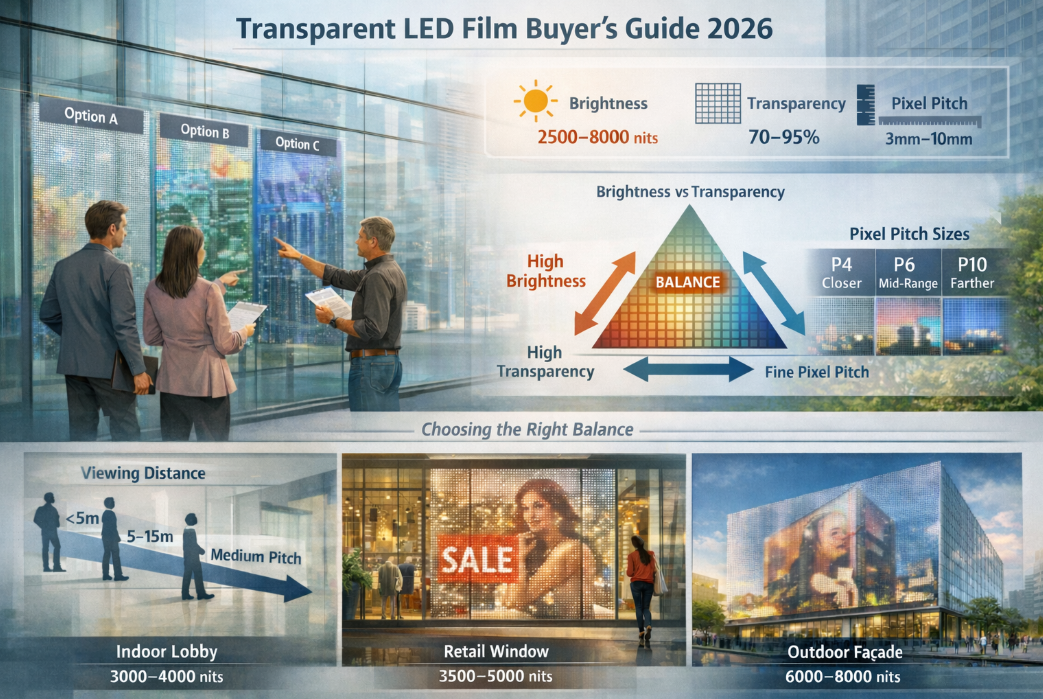

For indoor lobbies and malls, 2500–4000 nits is usually enough; retail windows in daylight often need 3500–5000 nits; outdoor façades typically sit at 5000–8000 nits.

Expect transparent LED film transparency between 70–95%; pixel pitch commonly ranges from about 2.6–15 mm depending on application.

Closer than 5 m: choose ≤3–4 mm pitch; 5–15 m: 4–8 mm; beyond 15 m: 8–15 mm is usually adequate and more transparent.

Higher brightness usually means more LEDs per square metre, which tends to reduce transparency and increase power consumption.

Very high transparency (90%+) looks great for see‑through façades but needs strong, bold content and enough brightness to avoid “ghostly” images.

For shop windows, balance is often around 70–85% transparency, mid pixel pitch (P4–P8) and 3000–5000 nits depending on sun exposure.

Ask suppliers to quote brightness at calibrated white, typical transparency on glass, and recommended viewing distance for the proposed pixel pitch.

Understanding Transparent LED Film and Why These 3 Metrics Matter Most

Transparent LED film is essentially an ultra‑thin, flexible PCB or conductive film with micro‑LEDs arranged in a grid, laminated onto glass. Compared with cabinet‑type transparent LED or mesh screens, the film adds minimal structural weight, follows gentle curves, and keeps the original glass line almost intact. You gain digital content on glass without building a secondary structure in front of it.

Brightness, transparency and pixel pitch are the three numbers that determine whether that promise holds up in real life. They jointly define what the human eye actually perceives: image contrast, legibility, and how “open” the space still feels. Many spec sheets list them independently, but on the engineering side they are tightly coupled by physics and manufacturing constraints.

Brightness (measured in nits) is your weapon against ambient light. In a bright atrium or sunlit street, a 1000‑nit display quickly washes out, while a 4000–6000‑nit film keeps text and graphics readable. Because transparent LED film has large open areas, it loses some perceived brightness compared with a solid LED cabinet at the same nit rating; that’s why films often sit in the 2500–8000‑nit range.

Transparency expresses how much light passes through the film. A typical transparent LED film offers about 70–95% light transmission, depending on LED density and conductor design. Higher transparency protects daylight and view‑through but reduces surface area available for LEDs, which in turn affects brightness and resolution.

Pixel pitch defines the centre‑to‑centre distance between LEDs. Smaller pitch (e.g. 2.6–4 mm) gives higher resolution and smoother gradients but needs more LEDs and more wiring. Larger pitch (8–15 mm) increases transparency and reduces cost and power, but content must be designed for distance and simplicity.

In real projects, different roles read these metrics differently:

Architects usually focus on transparency, daylight and façade integrity, and are sensitive to how the display looks when it’s off.

System integrators care about pixel pitch, power, control systems and how brightness will work against measured lux levels.

Procurement focuses on cost per square metre, energy consumption, reliability and warranty, and needs a clear way to compare unlike quotations.

Expert note: a “good” transparent LED film spec is rarely the highest number in each column; it’s the combination that fits your viewing geometry, glass type and business objective.

Brightness in Transparent LED Film: Nits, Ambient Light and Visual Impact

What brightness (nits) really measures and why transparent LED often needs more

Brightness is specified in nits (cd/m²), essentially how much light the display emits per unit area at a given white level. In lab conditions, this is straightforward; in front of a south‑facing glass wall, it isn’t.

Transparent LED film has two specific challenges:

Large open area means you see both content and whatever is behind the glass. If brightness is too low, background reflections overpower the image.

Glass introduces reflections and sometimes tint. A 3000‑nit module behind low‑iron glass behaves differently from the same module behind green‑tinted double glazing.

Industry data: 2025 supplier specs show typical transparent LED film brightness between 2500–8000 nits, with energy use around 200–400 W/m² at calibrated white.

Because of this, for the same visual impact you often need a brighter transparent film than an indoor LED wall in a dark auditorium.

Choosing brightness for indoor lobbies, retail windows and outdoor façades

A practical way is to start from ambient lux and work backwards, but most project teams don’t have continuous lux data. So we use ranges based on typical environments:

Indoor lobbies, offices, corridors with controlled lighting: 2500–3500 nits usually works, especially if glass is not in direct sun.

Shopping malls and atriums with skylights or strong accent lighting: 3000–4000 nits gives comfortable visibility without glare.

Retail shopfronts facing the street, no direct sun: 3500–5000 nits. This covers cloudy days and bright overcast conditions; you still use automatic dimming at night.

Retail windows or glass façades with direct sun certain hours: aim 5000–7000 nits and insist on automatic brightness control based on ambient light sensors.

Large outdoor façades functioning as media façades: 6000–8000 nits is common to compete with full daylight and city lighting.

Practical recommendation: ask suppliers to state brightness at “calibrated white, after factory uniformity adjustment,” not just LED chip capability, to avoid over‑optimistic numbers.

Tradeoffs of very high brightness: power consumption, heat, cost and light pollution

Pushing brightness has costs:

More LEDs per square metre or higher drive current raises power from ~200 W/m² toward 400 W/m² and beyond.

Heat increases, which matters on laminated glass where ventilation is limited; this impacts LED lifetime and adhesive performance.

In dense urban areas, regulators may limit nit levels at night due to light pollution; you may pay for capacity you’re not allowed to use.

Higher brightness configurations often come with lower transparency because LED density increases.

So “maximum nits” isn’t a smart spec. A better approach is to:

Define worst‑case ambient scenario (orientation, glazing, local climate).

Choose a brightness band that safely covers it.

Ensure auto‑dimming and scheduling are specified to control energy usage and comfort.

Transparency: Light Transmission, Visual Comfort and Storefront Integration

How transparency percentage is defined and measured in transparent LED film

Transparency is usually stated as a percentage of visible light that can pass through the film. In practice, it’s determined by the ratio of open area (gaps between LED tracks) to total area, plus the optical effect of conductors and substrates.

On spec sheets you’ll see claims like 85–95% transparency. The nuance:

Lab measurements may use a collimated light source and bare film.

In real installations, you add glass, interlayers, sometimes blinds or curtains behind the glass. Effective transparency becomes lower.

LED housings, bus bars and cabling at frame edges also affect perceived openness.

Expert view: any transparency number above 90% deserves a question: “Measured on film only or on glass? At what angle?” Not because it’s impossible, but because context matters.

Balancing see-through clarity vs advertising impact in glass façades and shop windows

Architects and tenants care about two opposite things: preserving the view out and making the campaign visible. Too much transparency with weak content leads to complaints that “the display doesn’t do anything”; too little transparency turns the glass into a media wall and kills natural light.

For typical scenarios:

Premium retail shopfronts: 70–85% transparency is often the sweet spot. You keep strong daylight and window merchandising while allowing bold, full‑colour content to read clearly.

Corporate lobbies and offices: 80–90% if messaging is more ambient (logos, patterns, low‑density information) and view‑through is a priority.

Large media façades on commercial buildings: 60–80% is acceptable because the main viewing distance is far, and the façade acts as a landmark.

A useful design trick is to vary transparency by zone: higher density (lower transparency) in key content areas and higher transparency elsewhere. Custom transparent film designs, like those Zhenmei Wisdom develops for crystal film screens, can be optimised for that.

When very high transparency (90%+) is not the best choice for your project

There’s a recurring mistake: choosing the highest transparency option assuming it’s always “more premium”. In practice:

At 90%+, each LED covers a smaller visual area; fine content such as small text or low‑contrast images gets lost, especially in bright environments.

To compensate, teams push brightness or saturation, which increases power and can make content look harsh at night.

The perception of image continuity suffers; at moderate viewing distances the display can feel “too sparse”.

High‑transparency film is excellent for subtle brand layers or night‑time accent patterns. But if the glass is meant to carry promotional messages during daytime, 70–85% transparency with stronger LED presence is usually more effective.

Pixel Pitch: Resolution, Viewing Distance and Content Design

How pixel pitch affects resolution and perceived image sharpness on transparent LED film

Pixel pitch directly defines how many pixels you can pack per square metre. A P3 film has roughly four times as many pixels as a P6 film, and so on. On transparent LED film, each pixel is typically a single or small cluster of LEDs arranged in rows and columns.

Smaller pitch:

Higher resolution and smoother gradients.

Lower transparency, more cost, higher power.

Better for close‑range content like product pricing or wayfinding.

Larger pitch:

Higher transparency and lighter visual presence.

Lower resolution; images and text must be large and simple.

Ideal for long‑distance branding, patterns or large‑format media façades.

Practical viewing distance guidelines for common pixel pitches in real projects

For conventional LED, many use the “pitch in mm ≈ minimum comfortable viewing distance in metres” rule. For transparent LED film, because the background helps “fill” the gaps, you can often be slightly closer, but don’t push it.

As a working table:

P2.6–P3.9: comfortable from ~3–5 m; suitable for retail interiors, small lobby displays and indoor installations where people walk close.

P4–P6: good from ~4–8 m; fits most shop windows, mall atriums and mid‑size glass walls.

P8–P10: works from ~8–20 m; typical for large façades where viewers stand across the street or in a plaza.

P10–P15: for landmark façades and long‑distance visibility; content should be bold, with large shapes and minimal fine detail.

Practical recommendation: stand at the expected main viewing distance and print your key visuals at the approximate pixel grid to check legibility before finalising pitch.

Aligning content design (text size, motion, color) with your chosen pixel pitch

Pixel pitch is not just a hardware decision; it locks in constraints for your content team:

Text: avoid using fonts thinner than 2–3 pixels at stroke width; on P8 and above, that often means 10–15 cm letter strokes for outdoor façades.

Motion: overly fast scrolling or small moving objects break up on coarse pitch; use slower transitions and large motion blocks.

Colour and contrast: on transparent film, low‑contrast designs disappear against busy backgrounds. Use strong contrast and avoid fine gradients for key information.

Teams that treat content design as an afterthought often blame the hardware when the real issue is mismatch between pixel pitch and creative direction.

The Brightness–Transparency–Pixel Pitch Triangle: How to Balance Tradeoffs

Why you cannot maximize brightness, transparency and resolution at the same time

Physically, all three metrics are competing for the same resources: area on the glass and electrical budget.

Higher resolution (small pitch) packs more LEDs; this reduces open area, decreasing transparency and increasing power.

Higher brightness either drives each LED harder or adds more LEDs, again reducing transparency and increasing heat.

Higher transparency forces larger gaps between LEDs and tracks, limiting both maximum resolution and brightness.

You can move the slider in one direction, but the others move with it. Any supplier claiming “ultra‑high brightness, ultra‑high transparency and ultra‑fine pitch in one product” deserves a very careful technical review.

Typical specification combinations and what applications they fit best

In real projects I often see clusters like:

Config A: 3000–4000 nits, 80–90% transparency, P3–P4

Indoor atriums, corporate lobbies, airports with controlled ambient light.

Config B: 3500–5000 nits, 70–85% transparency, P4–P6

Street‑facing retail windows, shopping malls, transport hubs.

Config C: 5000–8000 nits, 60–80% transparency, P8–P10

Large outdoor media façades, long‑distance city landmarks.

Zhenmei Wisdom’s transparent and crystal film screens typically sit in Config B and C ranges for public‑facing projects, with custom tuning when architects push for specific façade effects.

Simple decision framework: which metric to prioritize in different project scenarios

You can treat the triangle as a decision tool:

If the brief emphasises “do not block views / keep daylight”, prioritise transparency, then decide minimum brightness, and finally accept a coarser pitch with content adapted accordingly.

If marketing demands “daylight‑visible campaign content” at street level, prioritise brightness and pixel pitch first, and negotiate acceptable transparency with the architect.

For landmark façades with long viewing distance, prioritise pixel pitch appropriate to distance and façade scale, then brightness for city conditions, and allow lower transparency.

Actionable step: in early design workshops, ask stakeholders to rank the three metrics (brightness, transparency, resolution) from 1 to 3; use that ranking to filter supplier options instead of chasing absolute numbers.

Engineering Deep Dive: How Transparent LED Film Technology Drives These Metrics

Film structure and LED arrangement: how physical design sets transparency and pixel pitch

Transparent LED film generally consists of:

A transparent substrate (PET or similar) carrying ultra‑thin copper or silver‑nanowire traces.

SMD or micro‑LED packages mounted in rows/columns on those traces.

Adhesive layers designed to bond to glass (direct lamination) or to an intermediate carrier.

The spacing between traces and LEDs sets both pixel pitch and transparency. Wider pitch and slimmer traces mean more open area, hence higher transparency. More rows and heavier conductors enable higher brightness and resolution but reduce openness.

Flexible variants allow a certain bending radius, which is crucial for curved glass and creative shapes. This is also where other Zhenmei solutions, such as their LED holographic screen M Series, complement film when a 3D or volumetric effect is needed instead of purely 2D content on glass.

Optical and electrical design choices that influence brightness and energy consumption

Key engineering levers:

LED efficiency and binning: better chips deliver more nits per watt, reducing power draw at a given brightness.

Drive current and scanning method: higher current increases brightness but accelerates ageing; scanning schemes (e.g. 1/8 vs 1/16) impact peak current and power.

Power distribution: thin films need careful bus design to avoid voltage drop across large panes, which would cause brightness non‑uniformity.

Industry data: typical transparent LED films consume about 200–400 W/m² at full white in 2025; intelligent brightness control can halve real‑world average consumption.

Control systems, grayscale and refresh rate: hidden parameters that affect visual performance

Brightness, transparency and pixel pitch are visible on a datasheet, but other technical parameters shape perceived quality:

Grayscale (e.g. 14–16 bit) determines gradient smoothness and colour depth.

Refresh rate (≥1920 Hz, preferably 3840 Hz or above for cameras) avoids flicker and moiré on filmed content.

Brightness uniformity and colour calibration ensure that large glass surfaces look consistent, especially when combining multiple panes.

When comparing suppliers, ask for test videos shot on smartphone and professional cameras at both day and night to reveal any flicker or artefacts.

Application-Based Specs: How to Choose Metrics for Different Use Cases

Retail shopfronts and malls: balancing daylight, window displays and customer comfort

For a fashion or electronics flagship store, the glass is part of the merchandising. The display must:

Be bright enough to compete with daylight and interior spotlights.

Keep enough transparency so passers‑by still see mannequins or physical products.

Avoid glare that disturbs neighbouring tenants.

Typical spec direction:

Brightness: 3500–5000 nits, with auto‑dimming after sunset.

Transparency: 70–85%.

Pixel pitch: P4–P6 depending on distance from main walkway (often 4–8 m).

In malls, where ambient light is more controlled, you may reduce brightness and increase transparency slightly.

Corporate lobbies, airports and transport hubs: wayfinding, branding and safety constraints

Here the content is more informational and brand‑driven than purely promotional. Visual comfort and legibility are critical; safety regulations might limit glare and reflection.

Brightness: 2500–4000 nits is usually enough indoors.

Transparency: 80–90%, especially where staff work behind the glass.

Pixel pitch: P3–P5 for airport check‑in areas and wayfinding, where people can be close.

Airport and rail operators also care about MTBF and maintenance access. Film systems with modular replacement strips and robust control systems are easier to keep online for >50,000 hours.

Large glass façades and outdoor media: city regulations, long viewing distances and weather

On a 20‑storey glass façade, there’s no need for P3 resolution. What matters is long‑distance visibility, weather resistance and adherence to light pollution rules.

Brightness: 6000–8000 nits maximum, but with strong dimming curves for night‑time.

Transparency: 60–80%, to keep the building liveable for occupants.

Pixel pitch: P8–P15 depending on street distance.

Outdoor deployments must also consider IP rating, UV resistance of film and adhesives, and thermal expansion between glass and film. Work with suppliers who have real outdoor façade experience, not just indoor references.

ROI and Total Cost of Ownership: What Your Metric Choices Mean for Budget

How brightness and pixel pitch affect power usage, controller cost and cabling

More LEDs and more brightness drive both capex and opex:

Power: moving from a P8, 3000‑nit configuration to a P4, 6000‑nit one can more than double LEDs per m² and significantly increase power requirements. That affects electrical infrastructure and operating cost.

Controllers: higher pixel counts require more sending/receiving cards and more powerful processors.

Cabling: denser panels need more power feeds and data lines; on large façades, this changes riser design and maintenance access.

A proper TCO analysis should look at 5–7 years of energy usage, not just purchase price.

Impact of transparency and film weight on glass structure, installation and maintenance

Higher transparency designs often mean lighter film, which reduces added load to existing glass. Even though transparent LED film is already lightweight compared with cabinets, façade engineers still need numbers.

Film weight (often<2–3 kg/m²) plus any extra framing has to be checked against glass thickness and fixing details.

Installation method (dry stick, lamination, frame‑mounted) impacts replacement strategy and cleaning.

More dense, lower‑transparency films may require more cabling and supporting structures at mullions.

Simple ROI model: from footfall and impressions to payback period for transparent LED film

You don’t need a complex model to justify a transparent film investment; a simple approach works:

Estimate daily footfall or traffic viewing the glass.

Define value per thousand impressions based on brand or media rate.

Calculate annual “media value” of the façade.

Compare capex + 5‑year opex (energy + maintenance) against that media value.

For retail, even a modest uplift in conversion or brand recall across thousands of daily viewers tends to pay back a well‑designed film installation within a few years, especially when metrics are chosen to avoid costly over‑specification.

Installation and Environmental Considerations for Transparent LED Film

Glass compatibility, adhesion methods and curvature limits for flexible film

Not every glass is equal:

Tempered, laminated and double‑glazed units behave differently with heat and adhesives.

Some films are designed for direct lamination between glass layers; others are surface‑mounted with special adhesives.

Flexible films have a minimum bending radius; exceeding it risks cracking traces or stressing LEDs.

Early coordination with façade consultants and film manufacturers is essential. Share glass build‑up, expected thermal loads and any planned curvature before choosing a model.

Indoor vs outdoor specifications: IP rating, UV exposure, temperature and condensation

For indoor installations, IP and UV resistance demands are moderate, but HVAC patterns and condensation still matter. For outdoor use:

Require appropriate IP rating for both film and connectors.

Check operating temperature range against local climate.

Ask for UV tests on substrate and adhesive to avoid yellowing or delamination over time.

Actionable suggestion: include explicit test conditions (ambient temperature, lux level, viewing distance) in your RFQ, and ask suppliers to demonstrate brightness and colour under those conditions.

Common installation mistakes that ruin brightness and transparency performance

Typical pitfalls I see:

Mounting film behind tinted or patterned glass without revisiting brightness calculations.

Allowing cabling and junction boxes to clutter visible glass areas, spoiling transparency.

Skipping mock‑ups, leading to surprises about moiré, reflections or content legibility.

A small on‑site mock‑up with the proposed film, glass type and content avoids many of these issues.

Transparent LED Film vs Other Display Solutions on Glass

Comparing transparent LED film with traditional LED cabinets and mesh displays

Traditional LED cabinets offer high brightness and fine pitch but are heavy, opaque and need substantial support structures. Mesh LED reduces wind load and adds some transparency but still looks like a structure in front of the glass.

Transparent LED film:

Adds minimal weight, preserves the original façade line and can be retrofit.

Provides higher transparency and more “invisible when off” aesthetics than mesh.

May not reach the extreme brightness or ultra‑fine pitch of solid cabinets but is more than adequate for most glass applications.

Transparent LED film vs projection and LCD window displays: when each makes sense

Projection on glass (rear or front) struggles in high ambient light and needs space for projectors, with regular maintenance. LCD window displays are bright but fully block transparency and add bulk.

Transparent LED film is strongest where:

Daylight and see‑through are important.

Space for hardware behind the glass is limited.

The design intent is to integrate media into architecture rather than add a separate object.

How different technologies stack up on brightness, transparency, pixel pitch and lifecycle cost

In short:

LED cabinets: maximum brightness and resolution, minimal transparency, highest structure and weight.

Mesh LED: mid‑high brightness, medium transparency, visible structure, moderate weight.

Transparent LED film: mid‑high brightness, high transparency, minimal structural impact, competitive TCO for glass‑based applications.

For many commercial and architectural projects, film sits at the sweet spot of performance vs integration.

Common Misconceptions, Risks and How to De-Risk Your Specification

Why “higher brightness is always better” is a costly myth in transparent LED projects

Overspecifying brightness:

Increases capex and power infrastructure.

Forces aggressive dimming most of the time, so you rarely use the headroom you paid for.

Adds risk of glare complaints and regulatory issues.

Better to specify “sufficient brightness for defined conditions with wide dimming range” than chase maximum numbers.

Pitfalls in pixel pitch selection: over-spec vs under-spec for your content and distance

Two common errors:

Over‑spec (too fine pitch): drives cost and reduces transparency, while most viewers stand far enough that extra resolution is invisible.

Under‑spec (too coarse): key content elements, like pricing or logos, break up and become unreadable at normal distances.

A simple content‑first workshop with your creative team, using printed mock‑ups, usually solves this before hardware is ordered.

Procurement risks: incomplete RFQs, missing test conditions and inconsistent supplier data

Many RFQs simply list “transparent LED film for façade, P6, 5000 nits” and expect comparable bids. In reality, suppliers interpret transparency, brightness and testing differently.

Expert advice: specify test methods (e.g. brightness at D65 white, transparency measured on installed glass at 0° incidence), ambient conditions and viewing distances in your RFQ to force apples‑to‑apples quotations.

Advanced Operation and Maintenance for Long-Term Performance

Best practices for content scheduling and brightness control to extend product lifespan

LED lifetime is strongly related to drive current and operating temperature. To protect your investment:

Use automatic brightness control tied to ambient light, with upper limits for night hours.

Avoid 100% white full‑screen content for long periods; mix content and allow dark areas.

Schedule content “rest” periods or reduced brightness at low‑traffic hours.

These simple measures extend usable brightness over the >50,000‑hour life typical for modern films.

Cleaning, inspection and replacement strategies without damaging glass or film

Cleaning should respect both glass and film:

Use non‑abrasive cloths and neutral cleaners; avoid solvents that attack adhesives.

Inspect visually for hot pixels, colour shifts or delamination during routine façade maintenance.

Plan access for modular replacement of damaged strips or sections without removing entire panes.

Monitoring performance over time: color shift, brightness decay and when to retrofit

Over years, LEDs slowly lose brightness and may shift colour. A basic maintenance plan includes:

Annual brightness and colour checks at a few reference patches.

Logging any power‑supply failures or control errors.

Criteria for partial retrofit or recalibration when brightness drops below, say, 70% of original spec.

Technical FAQ: Brightness, Transparency and Pixel Pitch in Real Projects

What brightness level is recommended for different ambient light environments?

Controlled indoor: 2500–3500 nits.

Mall atrium / bright indoor: ~3000–4000 nits.

Retail window, no direct sun: 3500–5000 nits.

Outdoor façade / direct sun risk: 5000–8000 nits with auto‑dimming.

How does changing pixel pitch influence transparency and viewing comfort?

Smaller pitch increases resolution but reduces transparency and may make the glass feel “denser”. Larger pitch opens the view and can be comfortable at distance, but close‑up content becomes visibly pixelated.

Can transparent LED film be curved, used outdoors and remain energy efficient over time?

Many films are flexible to a specified bending radius and rated for outdoor use with proper IP and UV protections. With efficient LEDs and intelligent brightness control, real‑world energy use can stay around or below 200–300 W/m² on average.

What is the typical lifespan and warranty for transparent LED film installations?

Most professional suppliers quote >50,000 hours lifetime and offer 2–5‑year warranties, depending on configuration and environment. Always check that outdoor use, high brightness and local climate are explicitly covered.

Conclusion and Specification Checklist for Transparent LED Film Projects

Choosing transparent LED film comes down to managing the triangle between brightness, transparency and pixel pitch in the context of your glass, your content and your audience. Indoor lobbies want comfort and openness, retail windows need contrast in daylight without killing merchandising, and façades must respect both city regulations and building occupants.

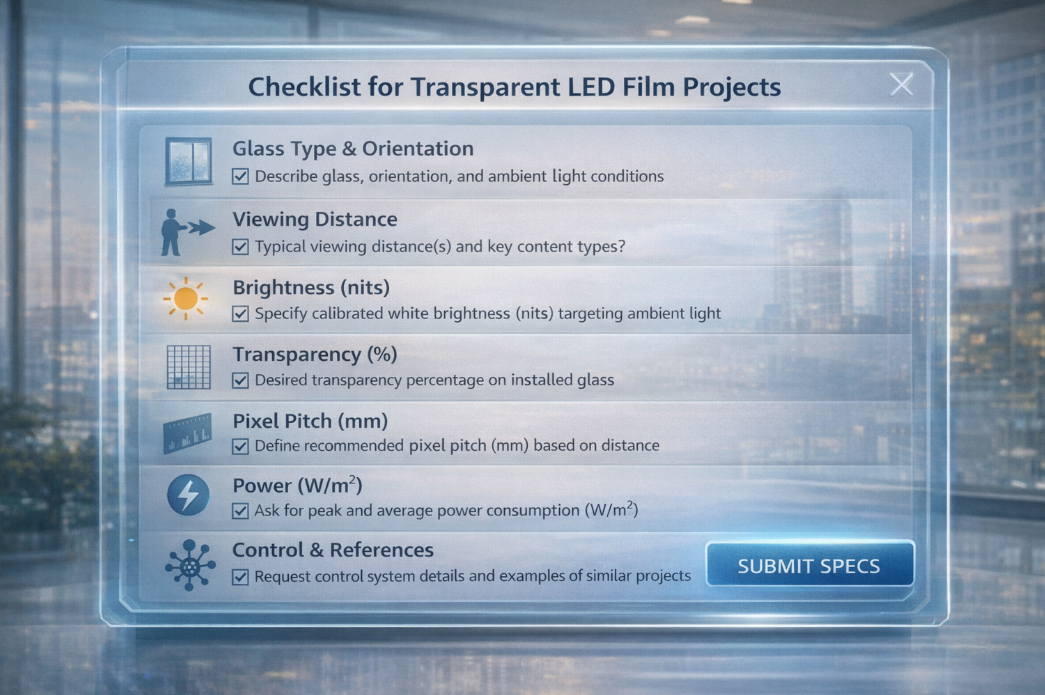

Practical checklist to brief suppliers:

Describe glass type, orientation and typical ambient light.

State priority ranking: brightness / transparency / resolution.

Specify target viewing distances and key content types.

Request proposed brightness (nits), transparency (%), pixel pitch (mm) with test methods.

Ask for power (W/m²), control system details, and references for similar projects.

When metrics start to push structural limits or city regulations, bring in an engineering‑focused partner early. Manufacturers like Zhenmei Wisdom, who combine R&D, production and project experience in transparent and holographic LED, can help validate assumptions before they become expensive revisions on site.

References and Further Reading on Transparent LED Film Specifications

Radiant LED: Transparent LED film technical specifications and application notes (2025).

Muxwave: Transparent LED Film 101 – performance metrics and viewing distance guidance (2025).

Industry supplier data sheets and façade engineering guidelines on transparent and media façade LED systems (2024–2025).