Description: A practical 2025 engineering guide for architects, facade consultants and owners on how to choose transparent 3D holographic LED mesh screens for building facades, including specs, safety, ROI and supplier selection.

Finding the right transparent 3D holographic LED mesh for a facade often feels like fitting a digital billboard into a glass curtain wall without upsetting the architect, the structural engineer or the landlord. I’ve watched projects stall because marketing wanted “floating 3D logos in daylight”, while engineering teams worried about wind load, heat and maintenance at 60 meters above ground. With media facades now expected to be both an architectural feature and a revenue‑generating asset, the choices you make on pixel pitch, transparency, structure and control system will stay with the building for a decade or more. The questions I hear most are always the same: what makes a holographic mesh truly daylight‑visible, how transparent can we go without killing the 3D effect, what will this do to our structure and maintenance budget, and how do we know a supplier is really facade‑grade rather than just repackaging rental LED? Let’s tackle those one by one.

Choosing a 3D Holographic LED Mesh for Your Building Facade

- A transparent 3D holographic LED mesh facade is a lightweight grid of LEDs mounted in front of or within the curtain wall that shows 3D visual effects while keeping views and daylight.

- Holographic LED mesh is better than standard mesh when your goal is high‑impact 3D visual depth, brand storytelling and “floating” objects rather than just big 2D advertising.

- For daylight visibility on urban facades, target ≥6000–8000 nits brightness, with stable contrast and calibrated color, especially on west‑facing glass.

- Pixel pitch is usually P6–P31 for large mesh facades; choose finer pitch only if your main audience is close (e.g., plaza or retail street).

- Transparency between 40–70% is the practical range where you still get good image quality without turning the facade into a solid wall.

- For outdoor use, look for at least IP65 front protection, corrosion‑resistant materials and confirmed wind‑load data matched to your structure.

- Expect lifespan claims around 80,000 hours, but ask to see real project references older than three years running similar conditions.

- In early design, involve architect, structural engineer and LED supplier together; poor coordination is the main reason media facades become over‑budget or under‑performing.

Understanding Transparent LED Mesh and 3D Holographic Facade Technologies

What is a transparent 3D holographic LED mesh facade in simple terms?

On a facade, a transparent LED mesh is essentially a series of slim LED strips or rods mounted with gaps between them. Those gaps let daylight, wind and views pass through, while the LEDs form a giant, low‑resolution display when lit.

The “3D holographic” part is not a magic floating hologram in mid‑air. It is:

- A transparent mesh structure that visually “disappears” when off.

- A content and control strategy that uses depth cues, motion parallax and brightness gradients so objects seem to float in front of the building surface.

- Sometimes a combination of staggered layers or curved mesh to increase perceived depth.

In practice, tenants inside still see out through the gaps; pedestrians outside see a media facade that can shift from subtle patterns to dramatic volumetric effects at night.

When is holographic LED mesh better than standard transparent LED mesh?

Standard transparent mesh is great when you mainly need:

- Simple advertising or logo playback

- Text, brand colors and basic animation

- A relatively lower cost per square meter

Holographic mesh makes sense when:

- The facade is a landmark and must stand out against other LED walls.

- The owner wants immersive storytelling, 3D logos or product visualizations rather than “flat” commercials.

- The architecture team cares about keeping the glass expression and not turning the tower into a solid LED box.

- You want flexibility: subtle architectural patterns on weekdays, high‑impact 3D shows for events.

One thing I always tell owners:

If your city is already full of 2D LED billboards, a well‑designed holographic mesh is how your building stops being “just another screen”.

Minimum technical specs for a daylight‑visible facade screen

From real outdoor projects, the lower limits that work in bright city conditions are roughly:

- Brightness:

- 6000 nits minimum for north/east facades

- 7000–8000 nits for west/south or glassy facades in strong sun

- Contrast:

- Deep blacks and shading hoods or a dark PCB/structure help performance in daylight.

- IP rating:

- At least IP65 front for rain and dust; IP54+ rear as a baseline.

- Operating temperature:

- Typically −20℃ to +50℃ for most climates; confirm derating curves.

- Control:

- Stable refresh rate (>3840 Hz) and grayscale for camera‑friendly campaigns.

Industry guides typically quote 6000–8000 nits for outdoor LED mesh as the sweet spot for daylight visibility on facades.

Understanding Transparent LED Mesh and 3D Holographic Facade Technologies

How transparent LED mesh screens work on building facades

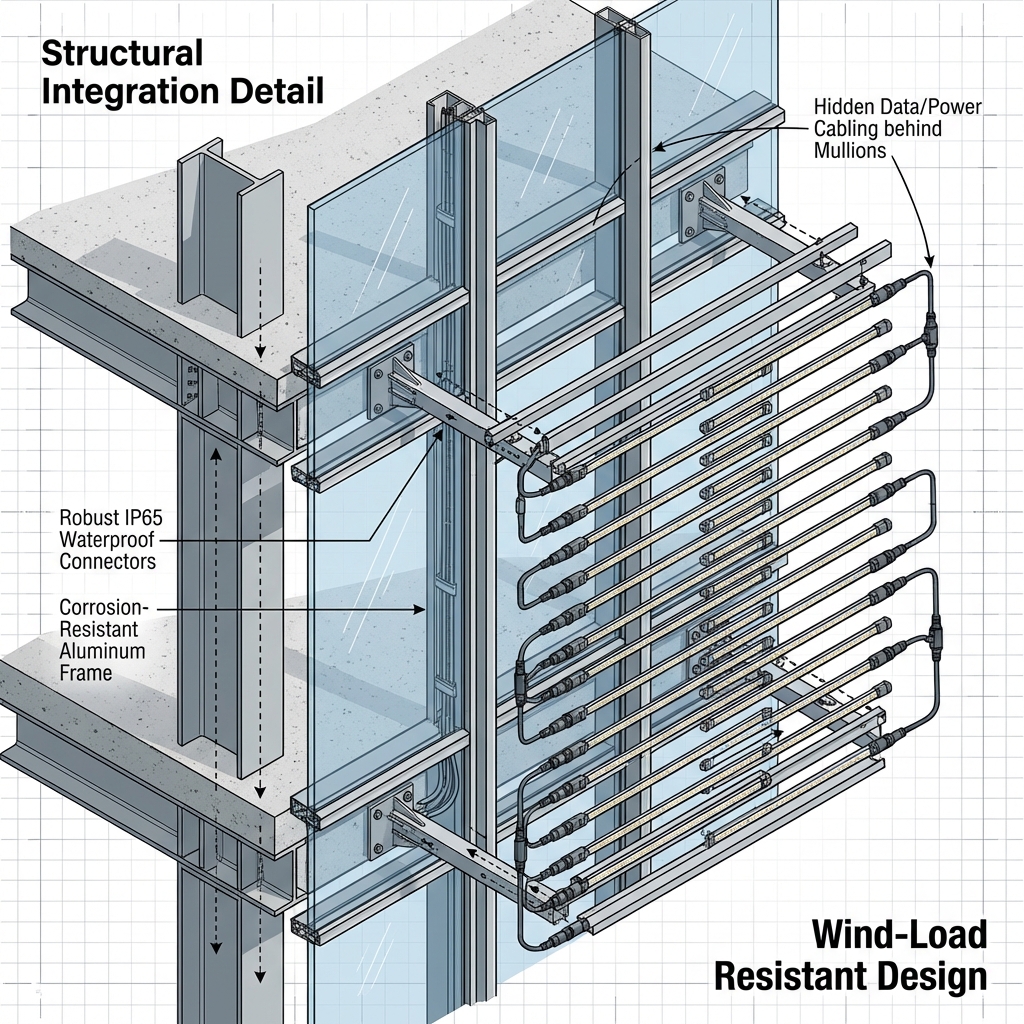

LED mesh uses discrete LED pixels mounted on slim bars or strings. Those bars are fixed to a lightweight aluminum or stainless steel frame. When installed on a facade:

- The mesh is anchored to a sub‑frame or directly to the main structure.

- Power and data are distributed through hidden cables behind mullions or in technical floors.

- The gaps between bars give a transparency of 40–90%, depending on pixel pitch and design.

Because each module is light and ventilated, mesh screens exert far less wind pressure than a solid LED cabinet, which is precisely why facade engineers prefer them.

What makes a LED mesh “3D holographic” instead of just transparent

Several elements turn a transparent mesh into a “3D holographic” system:

- Higher‑precision pixel alignment and control, so fine 3D content renders cleanly.

- Optimized transparency and pitch: enough void for a “floating” feel, but enough LED density so contours stay visible.

- Content pipeline designed for volumetric cues: shadows, lighting, zoom‑in paths, multi‑layer animations.

- Sometimes curved or folded mesh sections around building corners to enhance depth perception.

In factories like Zhenmei Wisdom’s in Shenzhen, holographic meshes are typically tuned with specific control systems and calibration to keep 3D effects readable even on very large surfaces.

From an engineering standpoint, “holographic” is about how hardware, optics and content cooperate to trick the eye into seeing depth, while the facade remains largely transparent in daytime.

Transparent LED film, LED glass and LED mesh: which are really suitable for outdoor facades?

Different transparent LED technologies behave very differently on real buildings:

Transparent LED film

Ultra‑thin, bonded directly to glass.

Best for indoor or semi‑indoor curtain walls protected from heavy rain and wind.

Limited service access; replacement is more complex.

LED glass

LEDs embedded inside laminated glass.

Strong architectural integration; ideal for new‑build projects where glass is specified from day one.

Heavy, higher structural demands, and difficult to retrofit onto existing facades.

LED mesh

Lightweight, air‑permeable and modular.

Ideal for large outdoor facades, especially retrofits.

Easy to install on steel sub‑frames, with good ventilation and access.

For most existing towers and retail boxes, mesh is the most realistic choice. Films and LED glass are more niche or fit best into high‑end, detail‑driven new projects.

Key Technical Specifications to Evaluate for Facade-Grade Holographic LED Mesh

Brightness and contrast for daylight and night-time operation on building facades

Brightness is often the first number buyers look at, and sometimes the only one. That’s risky.

For a facade‑grade holographic mesh, you want:

- 6000–8000 nits peak brightness, with software dimming for night‑time.

- Consistent brightness over time; look for ≤20% brightness drop over 3–5 years.

- Good contrast: dark structural elements and shielding around LEDs reduce washed‑out images.

At night, excessive brightness is a problem. It causes light pollution and complaints from neighbors. Make sure:

- The control system supports automatic brightness based on ambient light sensors.

- You can program “quiet” scenes for late hours – low‑motion, low‑brightness 3D content.

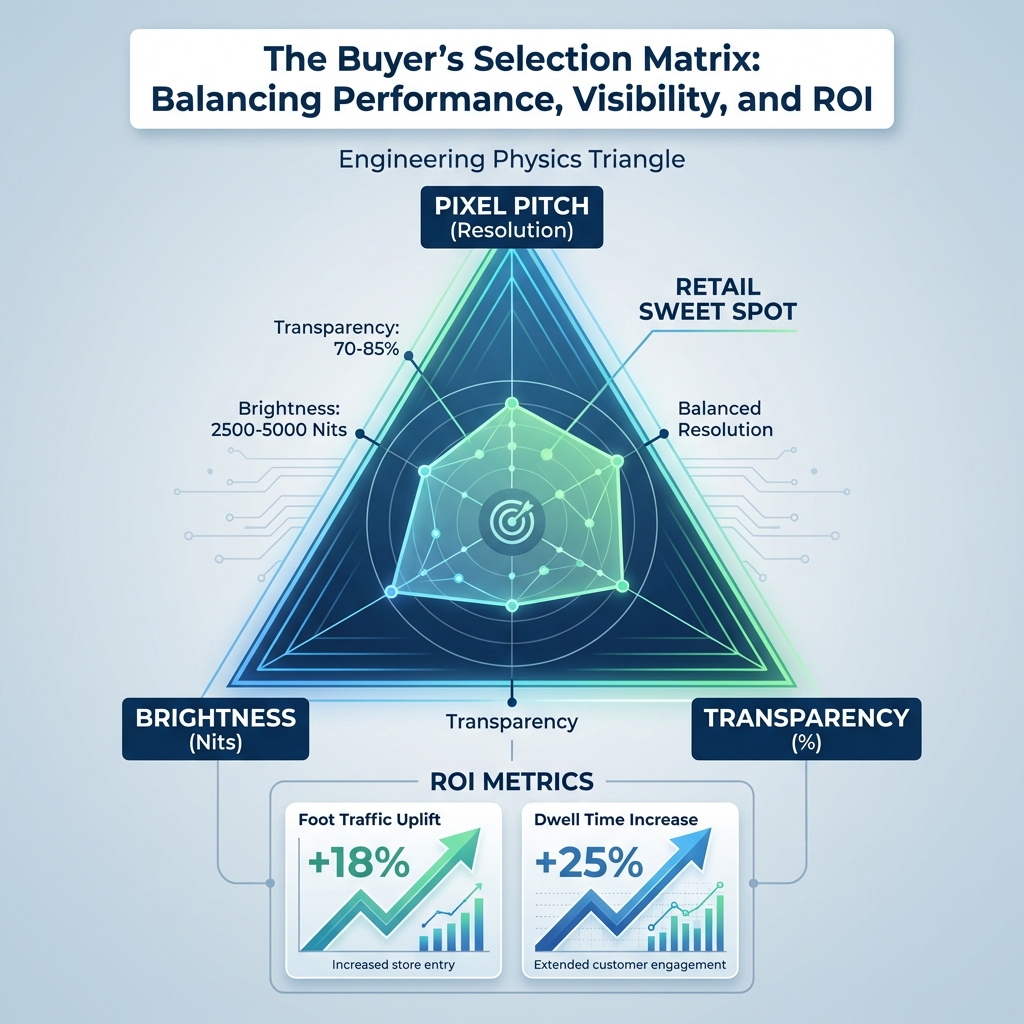

Transparency rate, pixel pitch and viewing distance: how to balance image quality vs architecture

Three parameters always interact:

- Transparency rate (void percentage, typically 40–90%)

- Pixel pitch (distance between LEDs)

- Viewing distance (how far viewers are from the facade)

For long‑distance city viewing (100 m+):

- Pitch P25–P31 can still look solid enough for branding and simple 3D shapes.

- Transparency can be higher, 60–80%, preserving more daylight and views.

For medium distance (30–100 m), such as a retail street:

- Pitch P10–P16 is more suitable for recognizable 3D logos and objects.

- Transparency often sits between 45–65% to keep image integrity.

For closer viewing (10–30 m), like a low‑rise flagship facade:

- Pixel pitch P6–P10 helps detailed 3D product visuals.

- You may accept slightly lower transparency (40–55%) in key zones.

A simple rule: if your main audience stands closer than 50 m, don’t specify a pitch larger than P20 for 3D holographic content.

Structural load, cabinet weight, power consumption and expected lifespan

Facade engineers will ask for hard numbers early:

- Module and system weight (kg/m²):

- Many meshes fall between 10–20 kg/m², far lighter than conventional full cabinets.

- Wind load:

- Manufacturers should provide tested wind‑load coefficients for the mesh geometry.

- Power consumption:

- Ask for both maximum and typical W/m²; holographic content rarely runs at 100% white.

- Lower average power means smaller electrical infrastructure and less heat.

Lifespan:

- Quality outdoor LED mesh often claims ≥80,000 hours (about 9 years at 24/7).

- Focus less on the number and more on supporting evidence:

- LED brand and binning policy

- Driver IC and power supply brands

- Real projects older than three years in similar climates

Holographic LED Mesh vs Traditional Transparent LED Mesh on Building Facades

Differences in 3D visual performance, depth effects and content possibilities

Traditional mesh is essentially a 2D canvas stretched across a building. It’s great for:

- Brand logos

- Simple typography

- Video clips at large scale

Holographic mesh, when paired with the right content, offers:

- Simulated depth: objects moving toward or away from the viewer.

- Layered scenes: background patterns plus foreground floating elements.

- Stronger “wow” factor for events, product launches and seasonal campaigns.

In practice, you’ll likely run a mix: calm architectural patterns 80% of the time, and more dramatic 3D sequences for special moments.

Impact on facade design: transparency, ventilation, natural light and indoor comfort

Both mesh types are ventilated, but holographic meshes often aim for a specific transparency range that balances:

- Enough LED density for 3D content

- Enough openings to keep daylight and cross‑ventilation

Architects worry about:

- Glare and reflections for office workers behind the mesh

- Visual clutter on carefully designed curtain wall grids

- Integration of mesh brackets with mullions and shading devices

Here, early collaboration is critical. A good supplier will overlay mesh layout on facade drawings, adjust module dimensions to align with mullions, and simulate how much daylight is lost inside different floors.

Cost, complexity and control system differences between holographic and standard mesh

Holographic mesh tends to cost more than standard mesh per square meter due to:

- Finer pitch or special mechanical design

- Higher requirements on calibration and control systems

- Often more demanding installation details

However, cost must be seen against the content potential and brand value. Many owners:

- Use part of the facade as holographic “hero zones”

- Keep the rest as more economical standard mesh

On the control side:

- Holographic facades usually need a media server capable of 3D timelines and layered composition.

- Standard mesh can run from simpler asynchronous or synchronous controllers.

If your budget is tight, concentrate holographic mesh where it matters most (e.g., podium or main street elevation) and use simpler mesh for secondary surfaces.

Outdoor Environment, Wind Load and Structural Safety for Media Facades

Wind load, IP rating and corrosion resistance: what facade engineers must check

For high‑rise media facades, wind is often a bigger problem than weight. Key checks:

- Wind load calculations according to local building codes (e.g., ASCE 7, EN standards).

- Mesh aerodynamic properties: open area ratio, shape of bars, anchoring points.

- Fatigue resistance of brackets and fasteners.

On protection:

- Minimum IP65 front; in coastal or industrial environments, higher corrosion resistance is vital.

- Marine‑grade aluminum, stainless steel hardware and UV‑resistant cables make a big difference after five years.

Fixing methods, sub-frame design and integration with curtain wall systems

Mesh is normally not fixed directly to glass. Typical approaches:

- Steel or aluminum sub‑frame fixed back to the main structure or concrete slabs.

- Brackets aligned with mullions, avoiding point loads on glass.

- Access walkways or maintenance rails in certain zones.

On retrofit projects, I often see under‑engineered sub‑frames cause more trouble than the LED itself. Involve a facade engineer who understands both curtain wall and secondary steel design.

Complying with local building codes, fire safety and electrical standards

Beyond “does it stick to the building”, authorities will ask:

- Fire performance of cables, plastics and coatings.

- Safe power distribution, grounding and surge protection.

- Emergency shutdown and integration with building management systems.

Check for:

- Relevant certifications (CE, UL, CCC or local equivalents).

- Test reports for EMC, high‑temperature, salt spray where applicable.

A serious manufacturer like Zhenmei Wisdom will be able to provide these documents early, not as an afterthought.

Brightness, Transparency and Pixel Pitch: Making the Right Trade-Offs

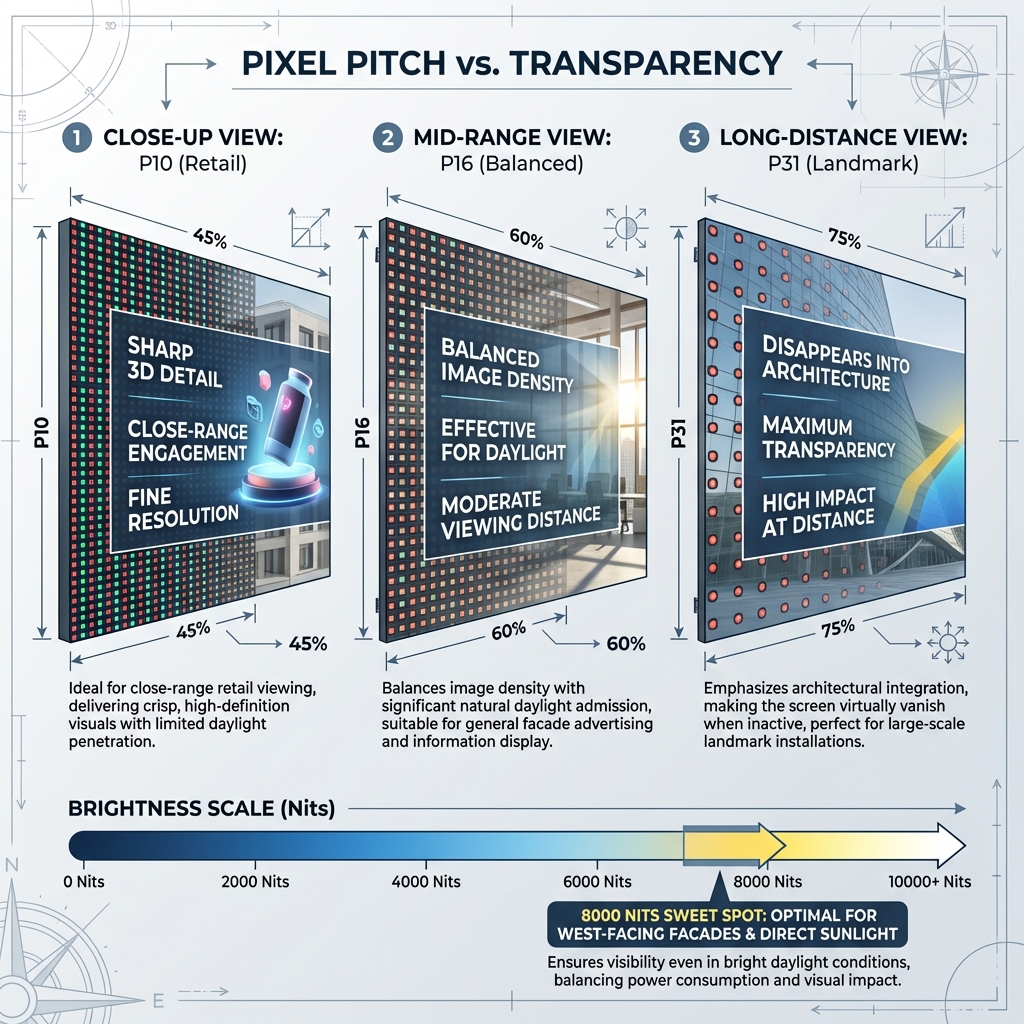

How to specify pixel pitch based on viewing distance and content type

To avoid guesswork, use a simple framework:

- Main viewing distance 20–40 m, detailed 3D content:

- P6–P10 recommended.

- Main viewing distance 40–80 m, mixed content (3D + text):

- P10–P16 works well.

- Main viewing distance >80 m, large 3D logos and patterns:

- P20–P31 is usually enough.

Content type matters as much as distance:

- Photorealistic products need finer pitch.

- Abstract 3D light sculptures can live with coarser pitch.

How transparency affects natural light, interior views and brand impact

Higher transparency:

- Better daylight and views for tenants.

- Less visual clutter inside.

- Weaker image density and 3D detail, especially in daylight.

Lower transparency:

- Stronger, more continuous images and 3D forms.

- Slightly darker interior, which can be positive for glare control in some offices.

For most commercial facades, a transparency range of 45–65% is the pragmatic “sweet spot” between tenant comfort and media performance.

Example configurations: recommended spec ranges for retail, corporate and landmark facades

Retail flagship (3–6 floors facing a busy street):

Pixel pitch: P6–P10

Transparency: 40–60%

Brightness: 6000–7000 nits

Emphasis on fine 3D content for products and campaigns.

Corporate headquarters (glass curtain wall, office use):

Pixel pitch: P10–P20

Transparency: 55–70%

Brightness: 5000–7000 nits

More architectural patterns and subtle 3D effects, limited late‑night brightness.

Landmark tower (long‑distance city views):

Pixel pitch: P16–P31

Transparency: 50–75%

Brightness: 7000–8000 nits

Large‑scale 3D logos, geometric animations visible from highways or across rivers.

Content, 3D Effects and Control Systems for Holographic Facade Displays

Types of 3D holographic content that work well on transparent mesh screens

Mesh is not a cinema screen. The best content respects its structure:

- Bold, high‑contrast 3D forms rather than tiny details.

- Controlled camera paths where objects move along the facade depth, not in random directions.

- Repetition and rhythm that align with the building grid.

Good creative studios treat the facade as an architectural object first, then a display. They test content on a virtual 3D model of the building before final rendering.

Media servers, control systems and remote management for large facades

For a serious holographic mesh facade, you want:

- Professional media servers capable of 3D timelines, multi‑layer playback and synchronization with lighting systems.

- Redundant main controllers and backup data paths to avoid full‑facade blackouts.

- Remote management:

- Health monitoring of power supplies, temperatures, and communication.

- Central scheduling for campaigns and brightness profiles.

A practical recommendation: require your supplier to provide a control topology drawing and a list of all third‑party software and hardware before final approval.

Avoiding common content mistakes that ruin the 3D holographic effect

Typical errors I see in early projects:

- Using low‑contrast footage that disappears at dusk.

- Overloading the facade with fast, flickering content that causes complaints.

- Ignoring the mesh gaps, so thin lines break apart and 3D illusions fail.

Ask for:

- A pilot content package designed specifically for your facade geometry.

- On‑site tests before final content production.

Common Misconceptions and Risks When Choosing Transparent Holographic Mesh

Marketing buzz vs engineering reality: what 3D holographic mesh can and cannot do

“Full hologram” language can be misleading. Holographic LED mesh cannot:

- Project images into mid‑air without a surface.

- Replace all indoor lighting or signage.

It can:

- Use transparency and depth cues to create strong 3D illusions from specific viewing angles.

- Turn a facade into a flexible media platform rather than a static light feature.

Pitfalls in choosing purely by transparency or price

Common traps:

- Ultra‑high transparency but poor 3D readability.

- Very low price relying on unbranded LEDs and power supplies, leading to early failures.

- Ignoring installation and steel structure costs, which often match or exceed LED hardware cost.

Always evaluate:

- Total system cost (LED + steel + power + control + content).

- Long‑term operating cost and service capability.

Risk checklist before signing a facade LED mesh contract

Before issuing a PO, verify:

- Wind and structural calculations are aligned with local codes.

- IP rating, salt‑spray and UV test reports match your environment.

- Clear maintenance strategy (access paths, spare parts list, response times).

- Real projects of similar scale and climate, ideally from the same manufacturer.

If a supplier cannot walk you through an existing project with drawings, photos and operating data, treat their proposal as experimental, not facade‑grade.

Maintenance, Reliability and Lifecycle Planning for Outdoor LED Mesh Facades

Access, modular design and front / rear maintenance strategies

On day one, everyone is excited about content; in year five, maintenance is what decides if the facade still runs.

You need:

- Clear access routes: BMU, gondolas, catwalks or rope access plans.

- Modular design: small, field‑replaceable modules and power boxes.

- Defined maintenance mode: front service (from outside) or rear service (from behind facade), depending on building design.

Typical failure modes for outdoor mesh screens and how to prevent them

The failures I see most often:

- LED pixel degradation or color shift from low‑quality bins.

- Power supply failures from heat or lightning surges.

- Connector corrosion and cable damage.

Prevention comes from:

- Proper surge protection and grounding design.

- Adequate ventilation and thermal management.

- Using industrial‑grade components and sealed connectors.

Planning for 80,000-hour lifespan: spare parts, warranty and service level agreements

Ask for a concrete lifecycle plan, not just a brochure claim:

- Spare parts policy: how many modules, power supplies and control cards will be stocked and for how long.

- Warranty specifics:

- LED brightness retention, color consistency, and allowed dead pixel rates.

- On‑site vs return‑to‑factory service terms.

- Service level agreement (SLA):

- Response time for critical issues.

- Regular inspection and cleaning schedule.

A manufacturer with in‑house R&D and production, like Zhenmei Wisdom, is usually more flexible on long‑term component continuity than pure traders.

ROI and Business Case: Is 3D Holographic Mesh Worth It for Your Building?

Cost components: hardware, steel structure, installation, content and operation

The LED price per square meter is only part of the story. A realistic budget includes:

- LED holographic mesh hardware.

- Steel or aluminum sub‑structure and brackets.

- Electrical works and control rooms.

- Initial content production and commissioning.

- Operating costs: electricity, service contracts, periodic cleaning and inspections.

Comparing ROI of holographic LED mesh vs traditional transparent mesh and static lighting

Static lighting:

- Lower upfront cost.

- Limited content flexibility; rebranding is expensive.

Traditional transparent mesh:

- Medium cost.

- Good for long‑term branding and advertising, but less impressive in crowded cityscapes.

3D holographic mesh:

- Higher upfront cost.

- Stronger differentiation and potential advertising value.

- Better aligned with digital media strategies and event‑based campaigns.

For many owners, even modest advertising revenue or sponsor partnerships can offset a significant portion of holographic mesh CAPEX over the life of the facade.

How to estimate advertising value and brand impact for media facades

A simple approach:

- Estimate daily impressions: traffic counts, pedestrian flows, sightlines.

- Benchmark local media costs (e.g., cost per thousand impressions for outdoor billboards).

- Factor in qualitative value: landmark status, social media exposure, tenant attraction.

Owners often use a mix of direct revenue (selling time slots) and indirect value (premium rents, brand positioning) in their ROI models.

Supplier Selection Checklist for Transparent Holographic LED Mesh Facade Projects

Engineering capability, case history and certifications to look for

Beyond price lists, evaluate:

- In‑house R&D and production versus pure trading.

- Number and scale of completed facade projects, not just rental screens.

- Certifications: CE, UL, EMC, safety and environmental reports.

A supplier focused on transparent and holographic displays, such as Zhenmei Wisdom, is more likely to understand facade‑specific issues than a generic LED vendor.

What should be included in a complete technical proposal and specification

Insist on a structured proposal that covers:

- Detailed technical datasheets (brightness, pitch, transparency, IP, power, weight).

- Control system architecture and redundancy.

- Preliminary structural load data and fixing concepts.

- Maintenance concept and access strategy.

- Draft content and control workflow.

A good proposal reads like an engineering document, not just a colorful brochure.

Questions to ask suppliers about structure, testing, warranty and long-term support

Some practical questions:

- How many similar outdoor mesh facades have you delivered, and where?

- Can we speak to at least one existing client?

- What tests have been performed for UV, salt spray and high/low temperature?

- How long do you guarantee availability of spare modules and components?

- Do you provide onsite supervision or turnkey installation through partners?

You can also browse the supplier’s product and project pages (for example, through resources like https://en.zmleds.com/l) to cross‑check claims and see real applications.

Facade Project Scenarios and Mini Case Studies

Large commercial tower: ultra-high brightness mesh for long-distance viewing

Imagine a 40‑story office tower next to a highway. The brief: visible from 1–2 km away, minimal disruption to tenants.

A workable setup:

- Pixel pitch: P25–P31

- Transparency: ~65%

- Brightness: 7000–8000 nits

- Content: slow 3D logo reveals and large‑scale geometric waves

Here, the ROI leans toward city branding and occasional campaigns rather than fine detail.

Retail flagship store: balancing transparency, 3D effects and interior daylight

A 4‑story glass box on a busy shopping street wants immersive product visuals without turning the interior into a dark cave.

Likely configuration:

- Pixel pitch: P6–P10

- Transparency: 45–55% on eye‑level zones, higher above.

- Brightness: 6000–7000 nits with aggressive night dimming.

- Content: product holographic animations, fashion shows, interactive campaigns.

The challenge is coordination between brand, architect and lighting designer so interior experience remains comfortable.

Corporate headquarters: integrating holographic mesh into a glass curtain wall

A tech company headquarters wants a “living facade” that can host subtle 3D data visualizations and event‑based shows.

Typical choices:

- Pixel pitch: P10–P16

- Transparency: 55–70%

- Brightness: 5000–6500 nits

- Content: abstract 3D patterns, brand signals for launches, discreet night scenes.

Here, the mesh becomes part of the building’s identity rather than purely an advertising surface.

FAQs About Transparent 3D Holographic LED Mesh Screens for Building Facades

Can transparent LED mesh be clearly seen under direct sunlight?

Yes, provided the mesh has sufficient brightness (6000–8000 nits) and good contrast. Content design also matters: high‑contrast 3D scenes with bold shapes read better in full sun than subtle gradients.

Is holographic LED mesh suitable for retrofitting existing facades?

Often yes. Because mesh is lightweight and ventilated, it is well suited to retrofits. The key questions are:

- Where to fix the sub‑frame back to structure.

- How to route power and data without harming the curtain wall.

- How to maintain access without major building modifications.

How to plan cleaning, inspection and safety checks for high-rise media facades?

Plan maintenance like you would for any high‑rise facade system:

- Integrate mesh access with existing BMU or rope access plans.

- Schedule regular visual inspections for brackets, cables and modules.

- Clean surfaces periodically in polluted or coastal environments.

Include these activities in your OPEX model from day one rather than treating them as surprises.

Conclusion and Next Steps for Specifying Your Holographic LED Mesh Facade

Key decision flow: from facade type to final mesh specification

A simple flow that works in real projects:

- Define facade type and primary viewing distances.

- Decide the role of the facade: landmark, retail, corporate or mixed.

- Choose a reasonable pixel pitch and transparency range.

- Check structural, wind and access constraints with engineers.

- Align content ambitions with control system capability and budget.

Always lock the engineering basics first (structure, IP, power), then refine visual ambition; not the other way around.

When to choose 3D holographic mesh and when a simpler transparent mesh is enough

Choose 3D holographic mesh when:

- Your building must function as a city‑scale media landmark.

- Brand and storytelling value justify higher CAPEX.

- You have the appetite to invest in proper 3D content and operation.

Standard mesh is enough when:

- You mainly need logos, text and simple patterns.

- Budget and engineering risk tolerance are limited.

In practice, many successful projects blend both approaches across different parts of the facade.

How to brief your architect, engineer and LED supplier for a successful project

In your initial brief, clearly state:

- Target viewing distances and audience.

- Desired level of 3D effect and content type.

- Constraints on daylight, tenant views and structural loading.

- Expected project timeline, warranty expectations and budget band.

Share this same brief with architect, facade engineer and LED manufacturer so they can co‑design a solution instead of working in silos. That’s where most of the cost and risk saves actually come from.

References and Further Reading on Transparent LED Mesh Facades

- “Transparent LED Display Buying Guide for Every Environment” – Vision LED Pro, 2024.

- “Transparent LED Mesh Screen Buying Guide” – Suntech LED, industry overview of mesh characteristics.

- Local building and facade design standards (e.g., ASCE 7, EN 1991, relevant fire and electrical codes) for wind, structural and safety requirements.