Standing in front of a flagship store or glass-walled lobby, you’ve probably asked the same question many of my clients do: “Could we turn this entire glass surface into a living 3D story without blocking the view or breaking the structure?” That’s exactly where LED holographic screen customization either makes your project or quietly kills it. With brands under pressure to prove every square meter of space delivers experience and ROI, a generic display rarely fits unusual façades, atriums, or complex retail windows. So it’s natural to wonder: Can LED holographic screens be customized in practice, or is it mostly brochure talk? Which parameters really matter—size, pixel pitch, transparency, content, control? And, most importantly, how do you balance creative ambition, engineering safety, and a budget your CFO will sign off?

Custom LED Holographic Screens at a Glance

- Yes, LED holographic screens can be customized in size, pixel pitch, transparency, shape, and content to match specific spaces and business objectives.

- Custom LED holographic screens are especially valuable for retail storefronts, malls, museums, experience centers, corporate lobbies, and architectural façades.

- A standard holographic LED screen works for simple rectangular windows and short-term events; you need a custom solution for large glass walls, curves, columns, or strict architectural constraints.

- Customizable parameters include physical dimensions, aspect ratio, pixel pitch, brightness, transparency level, mounting system, and integration with your control/CMS.

- Well-planned custom holographic LED display projects typically outperform printed and LCD signage in attention, dwell time, and perceived brand value.

- Key pricing drivers are area, pixel pitch, transparency, structural complexity, content production, and integration requirements.

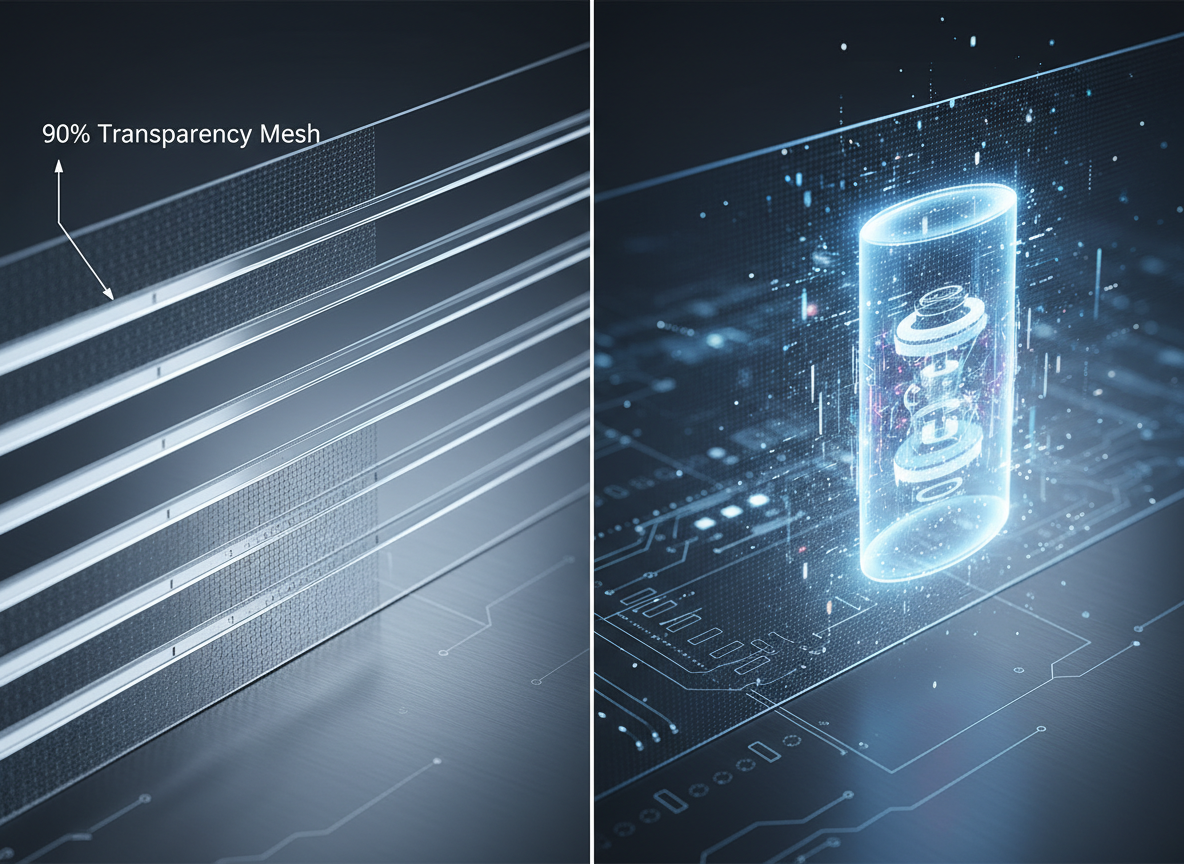

- Custom LED holographic screens integrate with glass using mesh, film, or modular frames that preserve 70–90% transparency while adding a digital “layer” to the façade.

- For most enterprises, custom holographic LED screens are worth the investment when tied to clear KPIs such as footfall uplift, lead capture, or media value.

What Are LED Holographic Screens and How Do They Work?

From transparent LED mesh to film: core types of holographic LED screen technology

When buyers say “holographic LED screen,” they are usually referring to high-transparency LED-based displays that create a floating, 3D-like image on glass or in open space. In practice, most projects use one of three core technologies:

- Transparent LED mesh or grille modules

- Transparent LED film or “crystal film”

- Ultra-thin fixed modules designed for holographic façades

Mesh systems use thin LED strips spaced to allow light through. Film solutions embed micro-LEDs or conductive traces within a transparent substrate that adheres directly to glass. Fixed-install holographic screens, like many M-series products, use narrow modules with pixel pitches such as P2.5, P3.91, P6.25, P8, or P10, combined to form larger transparent surfaces.

Industry data commonly cites transparency levels of up to about 90% for transparent holographic LED screen systems, depending on pixel pitch and structural design.

How holographic LED screens create floating 3D visuals on glass and open spaces

The “holographic” effect is less about true volumetric 3D and more about clever use of transparency, brightness, and motion. LEDs emit light in a defined plane close to the glass, while the viewer can still see through the gaps or transparent substrate.

Because the background is visible, content appears to float in the air—especially at night or against darker interiors. With well-designed 3D animations or parallax motion, the brain perceives depth, giving a pseudo‑holographic impression. In engineering terms:

- High brightness (often 2000–5000 cd/m²) helps the image “win” against ambient daylight.

- Controlled LED spacing and optical design preserve transparency while maintaining readable pixels.

- The content pipeline (media server, player, or controller) synchronizes frames so motion is smooth across all modules.

Transparent LED holographic signage vs traditional LED displays: key differences

Compared with traditional LED cabinets or LCD video walls, a transparent holographic LED screen behaves very differently:

- It does not fully block the view; transparency can range from about 70% to 90%.

- It is significantly lighter, which matters for glass façades and curtain walls.

- It requires more careful content design, because backgrounds and daylight affect readability.

- Structurally, it integrates with glass, mullions, or lightweight frames instead of heavy steel structures.

For buyers used to conventional LED panels, this is a mindset shift: you are not just buying a “screen,” you are adding a digital layer into your architecture.

Why Customization Matters for B2B Visual Display Projects

Brand impact and customer engagement: why custom holographic LED content performs better

In B2B projects, the question isn’t just “Can we play video?” but “Can this installation tell our story better than anyone else in the mall or exhibition hall?” Customization drives that.

A custom holographic LED screen display, matched to your architecture and brand, does a few things standard boxes simply cannot:

- Aligns visuals with the physical journey: entrances, escalators, focal corners

- Uses the full height of an atrium or window to stage large-scale product reveals

- Enables 3D-like scenes where physical products sit behind or in front of holographic content

In my experience, the combination of tailored screen geometry plus bespoke content is what unlocks the real holographic LED screen display benefits, not pixel specs alone.

When customized holographic LED screen display solutions beat printed and LCD signage

Printed signage still wins on simplicity and one-time cost, but it’s static. LCD walls win on image density but struggle with size, weight, and transparency. Custom LED holographic screen customization tends to outperform both in scenarios where:

- You need to keep natural light and views while adding dynamic storytelling.

- Architecture includes large glass areas where traditional displays would look intrusive.

- You’re running campaigns that change often—seasonal retail, product launches, touring exhibitions.

Once the system is in place, you can refresh content instead of re-building physical sets, which is especially attractive for premium retail and automotive showrooms.

Setting business objectives and KPIs for a customized holographic LED project

Before asking suppliers about pixel pitch, agree internally on what “success” looks like. Typical KPIs for custom holographic LED display projects include:

- Footfall uplift in front of the storefront or booth

- Dwell time in key zones (measured via sensors or manual counts)

- Lead capture, QR scans, or demo bookings triggered near the screen

- Media value if the façade is used as a communication channel

Practical advice: define 2–3 primary KPIs and a time horizon (e.g., six months post‑installation) before finalizing your specification; it keeps creative, engineering, and procurement aligned on trade‑offs.

What Can Be Customized: Size, Pixel Pitch, Transparency and Shape

Custom sizes, aspect ratios and modular combinations for façades, windows and atriums

At the hardware level, almost every serious manufacturer designs holographic LED modules as building blocks. That means:

- Standard module sizes (e.g., 125×1000 mm, 250×1000 mm, or 250×1175 mm) can be tiled into custom overall dimensions.

- You can follow the outline of existing window bays or façade grids rather than forcing a single giant rectangle.

- For atriums, vertical ribbons or stacked bands can frame escalators or voids.

A vendor with real engineering capacity can provide shop drawings that map modules to your mullions, keeping loads within glass and structure limits while still delivering the custom LED holographic screens your architect expects.

Choosing pixel pitch, brightness and transparency based on viewing distance and environment

This is where projects often go wrong when there isn’t enough technical guidance. The trade‑off is simple:

- Smaller pixel pitch (e.g., P2.5, P3.9) → better image at close viewing distances, lower transparency, higher cost.

- Larger pixel pitch (e.g., P6.25, P8, P10) → higher transparency, lower cost per m², but needs longer viewing distance.

Many transparent holographic LED projects land in the P3.9–P10 range, balancing transparency and clarity for viewing distances from 3–20 meters.

Brightness and transparency must also match the environment:

- Street-facing façades in bright daylight may require 3000–5000 cd/m².

- Indoor atriums with controlled lighting can operate at lower brightness and prioritize higher transparency.

Discuss specific lux levels and viewing distances with your supplier; “as bright as possible” is not always the best choice.

Curved, column-wrapped and irregular holographic LED designs for complex architecture

Custom holographic LED display solutions really shine when the architecture is challenging:

- Columns: narrow modules can wrap around round or square columns, turning them into 360° storytelling elements.

- Curves: flexible or narrow-frame modules follow gentle curves of glass or metal structures.

- Irregular shapes: cut‑outs for doors, signage, or structural beams can be accommodated with careful module layout.

This is where products designed for fixed-install holographic projection, such as an M‑series with modular widths and high transparency, are useful. A good engineering team will model sightlines, wind load, and maintenance access before committing to a final shape.

Designing Content for Custom Holographic LED Displays

What types of content work best on holographic LED displays: 3D animations, motion logos and product reveals

Not all content that looks good on an LCD will work on a transparent holographic LED screen. The background is always part of the picture. The formats that usually work best are:

- 3D product rotations and exploded views

- Motion logos and light trails that “wrap” around real objects

- Layered scenes where foreground elements are bright and simplified

- Short looped “moments” rather than long storylines

For holographic LED display for retail, a common approach is to synchronize content with physical product placement—e.g., a sneaker “breaking through” the glass near the actual product shelf.

Content design principles for depth, contrast and readability on transparent holographic screens

A few hard‑earned lessons from real projects:

- Use high contrast: bright foreground on darker or simplified backgrounds.

- Avoid dense text; use short, bold phrases with large point sizes.

- Embrace depth cues: shadows, perspective, and parallax motion enhance the holographic effect.

- Consider time of day; content that works at night may be washed out at noon.

Designers should work with real pixel grids, not just 16:9 mockups. Ask your manufacturer for a pixel map or template so your agency can preview how transparency gaps interact with your visuals.

Workflow between brand, creative agency and LED manufacturer for smooth content production

The most successful custom LED holographic display solutions treat content as a joint engineering task, not an afterthought. A typical workflow:

- Brand and agency define narrative, mood, and functional messages.

- LED manufacturer supplies technical constraints: resolution, frame rate, file formats, color space.

- Agency produces animatics and test loops.

- Manufacturer runs content on a demo rig or test module to check brightness, color, and moiré.

- Final tweaks are made based on recorded footage of the real environment.

When Zhenmei Wisdom (Zhenmei Wisdom (Shenzhen) Co., Ltd.) supports a project, for instance, our engineering team often joins early creative calls simply to prevent re‑doing weeks of animation because of avoidable technical mismatches.

Engineering and Integration Considerations for Customized Holographic Screens

Integrating custom holographic LED screens with glass façades, curtain walls and interiors

Engineering integration starts at the façade drawings. Key questions:

- Where will loads be transferred—glass, mullions, or independent frames?

- How will maintenance access be provided without disrupting operations?

- How do modules avoid shadow lines from mullions or sunshades?

Transparent LED holographic signage is usually mounted as:

- Adhesive film directly on glass (lightweight, minimal framing).

- Lightweight mesh or module frames fixed to mullions or suspended from beams.

- Hybrid solutions, where modules sit inside double‑skin façades.

Early co‑ordination with façade consultants and general contractors avoids unpleasant surprises later on site.

Power, data, control systems and CMS integration in enterprise environments

Behind every floating 3D visual is a fairly traditional control stack:

- Power distribution sized for total wattage plus headroom.

- Data networks from controllers to each module or group of modules.

- A control system or media server, which may integrate with your existing CMS or building systems.

From a systems perspective, treat a custom holographic LED screen as a specialized endpoint on your digital signage network: standardize protocols, security, and monitoring wherever possible.

Enterprise buyers increasingly want unified control—scheduling, content approval, and monitoring from a central platform. When specifying, ask whether the vendor supports:

- Standard video input (HDMI/DP), NDI or IP‑based distribution.

- Integration APIs, or at least stable control software.

- Remote diagnostics and alerting for faults.

Environmental, safety and regulatory requirements for permanent installations

Permanent installations bring additional constraints:

- Local building codes and fire safety regulations.

- Wind load and seismic considerations for outdoor façades.

- Heat management and ventilation around high‑brightness modules.

- Access for safe maintenance (lifts, catwalks, or from the inside).

A mature manufacturer will provide structural data, certificates, and test reports, not just a catalog. This is also where product lines designed for fixed installations, such as an LED holographic screen M Series, can simplify approvals thanks to tested transparency levels (around 70–90%) and predictable electrical characteristics.

Budget, Pricing and ROI of Customized Holographic LED Solutions

Key pricing drivers for custom LED holographic display solutions and typical budget ranges

Pricing is not just “cost per square meter.” Major drivers include:

- Total display area and module type

- Pixel pitch and brightness specification

- Structural complexity (curves, columns, special brackets)

- Indoor vs outdoor environment

- Content production scope and interactivity

- Integration with control systems and CMS

Small indoor showcases may sit in the low five‑figure USD range, while large media façades covering multiple floors can move into six or even seven figures when structure and content are included. Treat supplier quotes that ignore engineering and installation as incomplete.

How to estimate ROI: footfall uplift, dwell time, conversion and media value

Because many custom holographic LED display projects are brand‑driven, ROI is rarely just “sales per screen.” Common approaches:

- Measure footfall uplift at entrances compared with a baseline period.

- Track dwell time near the screen, especially in retail or museum contexts.

- Count specific actions: QR scans, app downloads, or lead forms initiated nearby.

- For external façades, estimate media value by comparing to OOH ad rates for similar locations.

Tie these metrics back to campaign objectives. For example, a luxury brand might value increased dwell time and social media content more than immediate conversion at the till.

Total cost of ownership: maintenance cycles, spare parts, upgrades and content refresh

Budget discussions should also cover the next five to seven years:

- Maintenance: cleaning, module replacement, controller updates.

- Spare parts strategy: keep a stock of modules and power units from the same batch.

- Content refresh: allocate an annual budget to keep visuals aligned with campaigns.

- Potential upgrades: controllers and CMS can often be upgraded without replacing hardware.

Ignoring TCO can make a “cheap” installation expensive over time if every content change requires re‑engineering.

Industry Use Cases: Retail, Events, Exhibitions and Architecture

Custom LED holographic displays for retail storefronts, malls and showrooms

Retail is where transparent holographic LED screen solutions are most visible:

- Flagship stores turning entire windows into 3D storytelling surfaces.

- Malls using hanging transparent banners that leave sightlines open.

- Automotive showrooms combining holographic layers with real vehicles behind glass.

In these scenarios, custom sizing and pixel pitch alignment to walkway distances are critical. A generic module wall may technically work, but a tailored layout that follows window divisions looks more premium and integrates with visual merchandising cycles.

Holographic LED installations for trade shows, museums and corporate experience centers

Events and exhibitions value flexibility and reusability. Custom holographic LED installations can be:

- Modular towers or portals that reconfigure between shows.

- Museum exhibits where content appears to float in front of physical artifacts.

- Corporate centers with semi‑permanent holographic scenes tied to brand narratives.

Because these spaces often have controlled lighting, you can use higher transparency and slightly larger pixel pitch without sacrificing visual impact.

Architectural applications: media façades, large glass walls and smart city projects

Architectural applications push both scale and regulations:

- Full‑building media façades that remain transparent for occupants.

- Smart city initiatives where municipal buildings become communication canvases.

- Mixed‑use developments using holographic LED display for retail on lower floors and subtle patterns on upper levels.

Here, collaboration between architect, façade engineer, and LED manufacturer is non‑negotiable. Decisions about transparency, maintenance access, and night‑time light pollution all flow back into product selection and customization.

Common Misconceptions, Risks and Vendor Selection Checklist

Myths about “true 3D holograms” vs what holographic LED screens actually deliver

One of the biggest misconceptions in this space is the word “hologram.” LED holographic screens do not produce true volumetric holography. They create:

- A 2D image plane with high brightness and partial transparency.

- A perceived 3D effect driven by content design and viewing angle.

Setting the right expectations with stakeholders early avoids disappointment and legal trouble if marketing uses the term loosely.

Technical and commercial risks: over-brightness, poor pixel pitch choices, weak structure and content mismatch

Common failure modes in custom holographic LED projects:

- Over‑bright screens causing glare, complaints, or regulatory issues.

- Pixel pitch too coarse for viewing distances, making content look “broken.”

- Under‑engineered mounting systems that worry façade engineers or inspectors.

- Beautiful content that ignores transparency, becoming unreadable in daylight.

Red flag: if a vendor’s proposal talks only about “P3.9 high brightness” and “90% transparency” but never asks for your plans, sections, or viewing distances, their customization is likely superficial.

How to evaluate a custom holographic LED supplier: R&D capability, references and service model

When you assess potential partners, treat it like choosing a long‑term technical collaborator, not just a screen vendor. Look for:

- In‑house R&D and production, not pure trading.

- Reference projects similar in scale and environment to yours.

- Engineering support for structural, electrical, and control integration.

- Clear after‑sales service model—SLA, spare parts, remote support.

Manufacturers like Zhenmei Wisdom that combine transparent LED, holographic screens, and flexible solutions under one roof can often propose better‑integrated systems than single‑product resellers.

Implementation Roadmap, FAQs and Key Takeaways

Step-by-step roadmap: from requirements and concept to prototyping, installation and commissioning

To de‑risk your project, walk through a structured roadmap:

- Requirements & site survey – define objectives, KPIs, and measure glass, structure, and power.

- Concept & feasibility – align creative ideas with structural and budget constraints.

- Engineering & mock‑ups – develop detailed drawings and, ideally, a small‑scale prototype.

- Manufacturing & factory acceptance – confirm performance (brightness, transparency, control).

- Installation & commissioning – integrate with power, data, CMS; calibrate brightness and color.

- Content fine‑tuning – adjust visuals based on real‑world viewing and ambient light.

- Handover & training – document systems and train operations and maintenance teams.

Frequently asked questions about custom sizes, integration with glass and investment value

Can LED holographic screens be tailored to unique sizes?

Yes. Modules can be combined into almost any size or aspect ratio, as long as glass and structure can carry the load.What elements of a holographic LED screen can be customized?

You can usually customize size, pixel pitch, brightness, transparency, frame design, mounting method, and of course content.How do custom holographic screens integrate with architectural glass?

Depending on the product, they can adhere directly as film, mount on lightweight frames attached to mullions, or sit inside double façades while keeping transparency.Are custom holographic LED screens worth the investment?

For spaces where brand experience, visibility, and media value matter—flagship retail, lobbies, experience centers—the long‑term impact typically justifies the upfront cost if KPIs are defined.

Key takeaways and reference links for further research on holographic LED screen customization

Three closing thoughts for business buyers:

If you remember one thing, let it be this: customization is not just about cutting modules to size; it is the alignment of hardware, architecture, and content around clear business outcomes.

Second, insist on engineering‑backed proposals—drawings, load calculations, and control diagrams—not just product datasheets. Third, bring your content and marketing teams into the conversation early; the most successful custom LED holographic screens are those where the creative idea and the physical space evolve together.

Conclusion

LED holographic screen customization is absolutely possible, and in 2025 it is mature enough for serious enterprise deployment—as long as you treat it as an integrated system, not a gadget. Custom LED holographic screens can adapt to unique sizes, glass geometries, and brand stories while preserving transparency and structural integrity. The real value appears when you combine appropriate pixel pitch, brightness, and transparency with content designed specifically for a transparent medium and a control system that fits your existing digital ecosystem. If you are planning a project, start with clear KPIs, share accurate site data with your shortlisted suppliers, and ask them to demonstrate not only products but also their engineering and content workflows. That approach gives you the best chance of turning your glass into a reliable, high‑impact digital asset rather than an expensive experiment.

References

- OneDisplay Group – Transparent & Holographic LED Screen Technology Overview, 2025

- LEDKUL – Pixel Pitch Options and Performance Considerations for Transparent LED Displays, 2025

- AVIXA (Audiovisual and Integrated Experience Association) – Recommended Practices for Large-Format Display Systems