A practical 2026 buyer’s guide comparing indoor, semi‑outdoor and outdoor transparent LED screens, with specs, IP ratings, ROI and selection tips for commercial projects.

Standing in front of a glass façade, many project owners tell me the same thing: “We want a stunning digital layer, but we can’t turn this building into a black box.” Transparent LED screens promise the best of both worlds, yet in real projects the big debate quickly becomes: indoor type or outdoor type, and is there a “semi‑outdoor” middle ground we can trust? With stricter city media regulations, rising energy costs and marketing teams pushing for brighter content, choosing the wrong specification can mean poor visibility, water damage or a system that never reaches its expected lifespan. So the real questions are: where are LED transparent screens truly suitable, how do indoor, semi‑outdoor and outdoor versions differ in brightness, IP rating and structure, and how do you translate all of this into a robust specification instead of a guess?

Where Can You Use Transparent LED Screens and What’s Different?

- Indoor transparent LED screens are ideal for shop windows, showrooms and lobbies with controlled temperature and no direct rain.

- Semi‑outdoor transparent LED is for under canopies, atriums or stations where there is daylight and occasional wind or moisture but limited direct rain.

- Outdoor transparent LED screens require IP65 or higher protection, high brightness and structural engineering to face direct sun, wind and rain.

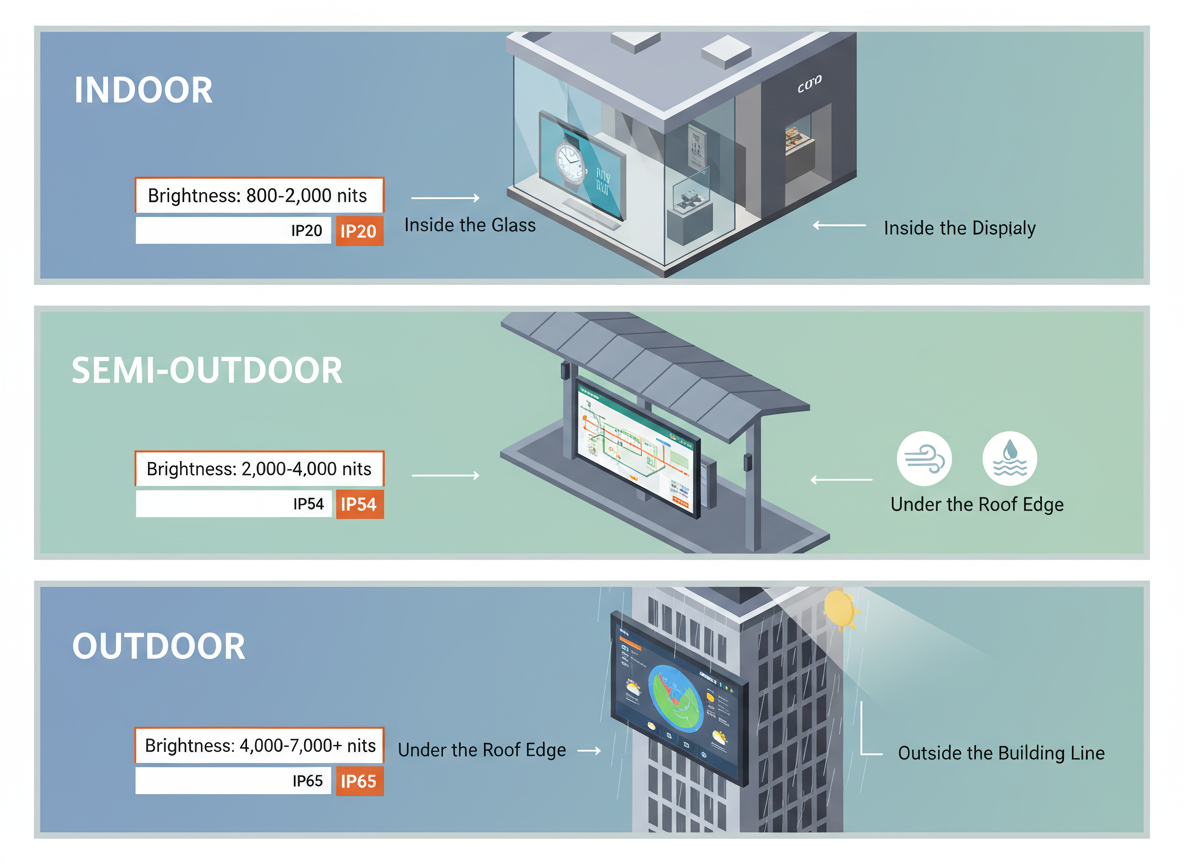

- As a rule of thumb, indoor brightness is usually 800–2,000 nits, semi‑outdoor 2,000–4,000 nits, outdoor 4,000–7,000+ nits.

- Indoor models focus on finer pixel pitch and higher transparency; outdoor versions sacrifice some transparency for strength and weatherproofing.

- You must choose outdoor‑grade transparent LED whenever the screen is directly exposed to rain, dust, UV and strong wind.

- Semi‑outdoor solutions are a good compromise when content must be visible in bright ambient light but full outdoor engineering is not necessary.

- For B2B projects, the safest approach is to define environment, brightness and IP rating in the spec, then match product series instead of just saying “transparent LED.”

Where Can You Use Transparent LED Screens and What’s Different?

At a glance: indoor, semi‑outdoor and outdoor transparent LED use cases

In real projects, “indoor vs outdoor” is often too simplistic. We typically see three practical environments:

Indoor: the LED is behind glass or fully inside the building envelope, in air‑conditioned space, not exposed to rain. Examples include luxury retail shop windows, car showrooms, museums and corporate lobbies.

Semi‑outdoor: the display is installed in an open atrium, under a canopy, in a station concourse or stadium concourse where it faces bright daylight, wind and some humidity, but is still partially sheltered from direct rain.

Outdoor: the LED modules, power supplies and structure are fully exposed to the weather on building façades, glass curtain walls, free‑standing frames or outdoor storefronts on the street.

You can think of it as three “layers” from the building’s perspective: inside glass, under the roof edge, outside the building line.

Key differences in brightness, protection level and cost in one view

The same content that looks vivid in a dim lobby can be completely washed out behind sunny glass. That’s why brightness, IP rating and total system cost move together as you go from indoor to outdoor:

Indoor transparent LED: lower brightness, typically 800–2,000 nits, IP20–IP31, lighter structure, more transparent (60–90%), lowest cost per square meter.

Semi‑outdoor: mid‑range brightness, often 2,000–4,000 nits, IP43–IP54, some sealing and better heat dissipation, moderate cost.

Outdoor: high brightness, 4,000–7,000+ nits for daylight and partial sun, IP65 or above at the front, reinforced modules and frames, highest cost and engineering effort.

Practical rule: every step up in environment (indoor → semi → outdoor) usually adds 20–40% to the hardware and structure cost, but it greatly reduces failure risk.

When indoor screens are enough and when you must choose outdoor‑grade

From a buyer’s standpoint, the biggest mistake I still see is using indoor transparent LED right behind a sun‑facing glass wall and calling it “indoor.” If the glass faces south or west, with strong afternoon sun, you should treat that as at least semi‑outdoor in terms of brightness.

Choose indoor only when:

- The glass is not strongly sun‑lit (e.g., north‑facing or shaded street).

- The screen is set back from the glass and ambient light is moderate.

- There is no chance of rain or condensation reaching the modules.

You must choose outdoor‑grade transparent LED when:

- The modules see rain, water spraying, dust or direct wind.

- The display is mounted on an external façade or exposed structural frame.

- Local building codes classify the installation as outdoor media façade.

Semi‑outdoor is appropriate when the display is open to daylight and occasional wind, but the roof and architecture already provide part of the protection.

Understanding Transparent LED Screen Technology and Construction

How transparent LED screens work: structure, LED arrangement and control system

A transparent LED screen is essentially a grid of LED pixels mounted on narrow strips or PCBs, arranged in vertical or horizontal bars with gaps between them. These “slats” are fixed to a lightweight frame, allowing natural light to pass through.

The core components are:

- LED strips/modules with SMD or sometimes COB LEDs.

- Driver ICs and receiving cards that decode image data.

- Power supplies and low‑voltage cabling.

- A control system (sending card, video processor, media player).

Compared with traditional LED cabinets, the open‑frame design and wider spacing between rows or columns provide transparency. The control system is similar, but content often needs optimization because there is no solid black background.

Transparency, pixel pitch and brightness: how they interact in real projects

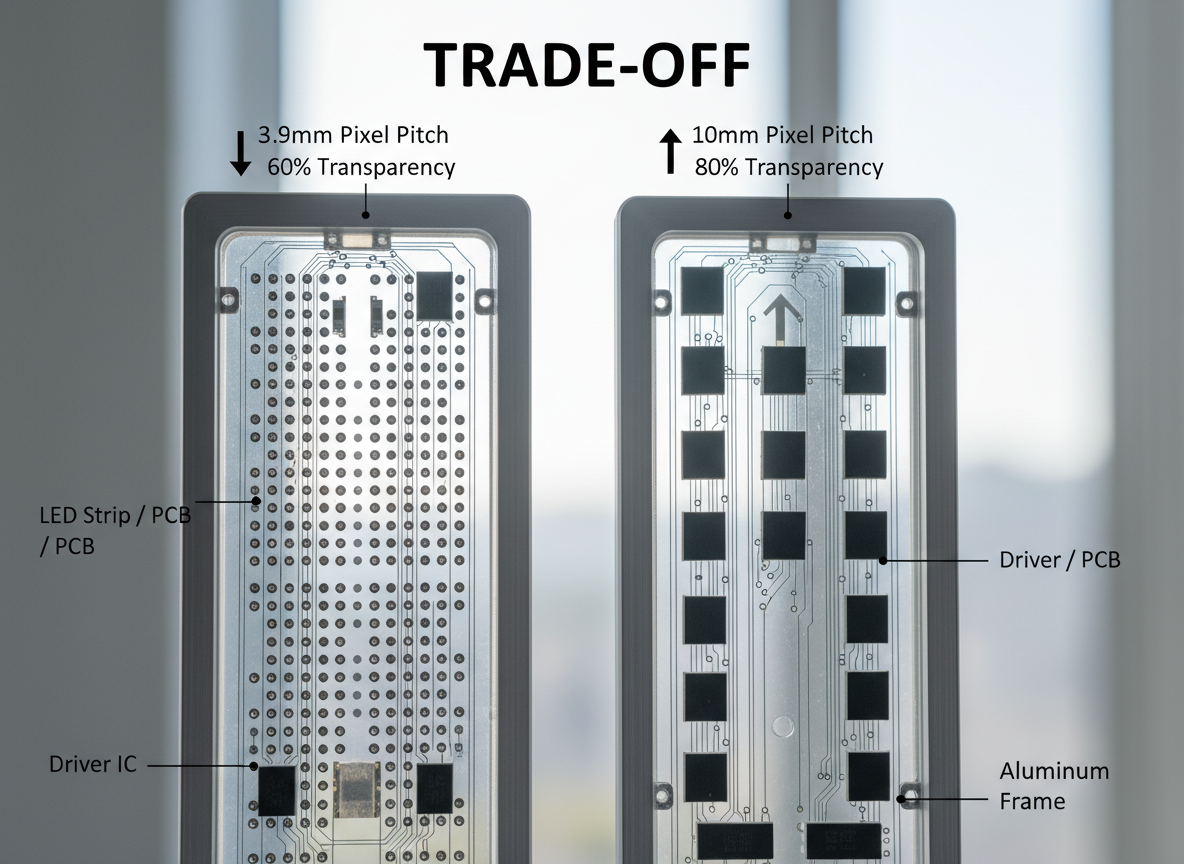

In design meetings, it’s common to hear: “We want 80% transparency and 3 mm pixel pitch.” Technically possible? In many cases, no. There is a trade‑off:

- Pixel pitch (distance between pixels) affects image clarity and minimum viewing distance.

- Transparency comes from the gaps between LEDs and strips; more LEDs mean fewer gaps, hence less transparency.

- Brightness depends on LED type, drive current and density.

For indoor transparent screens on shop windows, a pixel pitch of 3.9–7.8 mm with 60–70% transparency is a practical sweet spot. Viewers stand 3–8 meters away, and product displays remain visible behind the screen.

For outdoor façades, pixel pitch is often 8–25 mm with 40–70% transparency because viewing distance is longer and the structure must withstand wind.

Expert note: smaller pixel pitch always pushes you toward lower transparency or higher cost; defining the realistic viewing distance first avoids over‑specification.

Cabinet, frame and glass integration: what changes from indoor to outdoor designs

The same electronics can be packaged in very different ways:

Indoor transparent LED often uses lighter aluminum frames or customized rails mounted directly to the glass or a slim steel frame. Weight and aesthetics are priorities.

Semi‑outdoor configurations add drainage paths, better cable protection and sometimes conformal coating on PCBs to handle humidity.

Outdoor transparent LED uses robust extruded aluminum or steel frames, with sealed modules, gasketed joints and dedicated mounting brackets engineered for wind load and thermal expansion.

When integrating with glass curtain walls, details like thermal isolation, access paths for maintenance, and the sequence of glass vs LED installation become critical engineering questions, not just “where do we hang the screen.”

Indoor Transparent LED Screens: Ideal Scenarios, Specs and Limits

Typical indoor applications: retail windows, showrooms, exhibitions, corporate lobbies

Indoor transparent LED screens shine where brands want a digital layer without sacrificing openness:

- Fashion and luxury storefronts using full‑height glass for storytelling while keeping the store bright.

- Automotive showrooms overlaying content on cars behind the glass.

- Exhibition stands that change themes from event to event without re‑building structures.

- Corporate lobbies that want a digital façade but also want visitors to see through to the interior space.

In these scenarios, indoor climate, controlled lighting and easier access for maintenance make indoor transparent models attractive and cost‑efficient.

Recommended indoor specifications: brightness range, pixel pitch, transparency and viewing distance

For indoor use, a few ranges work well in 80–90% of projects:

- Brightness: 800–1,500 nits is usually sufficient; if you face strong ambient light from outside, consider 2,000 nits.

- Pixel pitch: 3–6 mm when viewers are within 3–8 meters; up to 10 mm for larger lobbies and atriums.

- Transparency: 60–85% depending on how important the view through the glass is vs image solidity.

- Viewing distance: minimum 3× pixel pitch as a simple rule (for 5 mm pitch, avoid critical content closer than ~15 m).

Actionable tip: ask your supplier for a brightness dimming curve and test content at 30–40% brightness at night; overspecifying brightness without dimming planning creates glare and wastes energy.

Installation and environment considerations for indoor glass and storefronts

Even indoor installations can cause trouble if basic details are ignored:

Heat: glass façades can trap heat. Ensure there is at least some air gap and vertical airflow behind the modules, especially for long walls.

Reflections: printed vinyl on the back of the glass or interior lighting can help boost perceived contrast. Content with strong motion also compensates for lower black level.

Access: plan how to reach every module for maintenance. Front access through glass is rarely practical; removable internal catwalks or hinged frames are common solutions.

Zhenmei Wisdom, for instance, often combines flexible transparent modules with customized aluminum rails to follow the building’s mullion lines while keeping maintenance zones accessible.

What Semi‑Outdoor Transparent LED Really Means and When to Use It

Defining semi‑outdoor: under canopies, arcades, atriums and partially exposed spaces

“Semi‑outdoor” is one of the most abused terms in LED. In transparent LED projects, we classify semi‑outdoor as:

- Installations directly facing daylight, possibly even some indirect rain or fog,

- Located under a roof, canopy, arcade or deep façade overhang,

- Exposed to higher temperature ranges and humidity than indoor spaces, but not to full driving rain from all directions.

Typical examples include open‑air shopping streets with roofed walkways, train and metro station halls open to the sides, sports stadium concourses and airport drop‑off canopies.

Key semi‑outdoor requirements: brightness, basic waterproofing and ventilation

Once you step into semi‑outdoor, indoor specifications are no longer enough:

Brightness: 2,000–4,000 nits to remain visible in bright ambient light and through potential reflections.

IP rating: at least IP43 or IP54 at the front for protection against splashing water and dust. Drive electronics should be protected by housings or conformal coatings.

Temperature and UV: components and housing materials must tolerate wider temperature swings, plus UV exposure where sunlight reaches the modules.

Ventilation is crucial. Semi‑outdoor spaces can become hot boxes, so modules should have sufficient open area at the back, and cabling should be routed to avoid heat pockets.

How to choose semi‑outdoor transparent LED screens for malls, stations and stadiums

For transport hubs and retail complexes, the choice is often between overspecifying to full outdoor or taking a calculated semi‑outdoor approach.

Consider:

- Whether wind‑driven rain can reach the modules at any angle.

- Night‑time brightness requirements to avoid light pollution or driver distraction.

- Maintenance accessibility in public spaces with limited downtime windows.

Project guidance: when in doubt, specify semi‑outdoor as “indoor electronics with outdoor front protection,” and insist on lab test reports for IP and temperature cycling; this is where cheaper products most often fail.

A semi‑outdoor transparent series also works well when you want a thinner visual profile than a heavy outdoor façade system but still need extra robustness.

Outdoor Transparent LED Screens: IP65 Protection and Daylight Visibility

Typical outdoor scenarios: building facades, media façades and outdoor storefronts

Outdoor transparent LED screens are essentially digital architecture. They live on:

- Glass curtain wall façades as media façades.

- Standalone steel structures or mesh frameworks covering entire building sides.

- Street‑facing storefront windows where there is no deep canopy.

- Bridges, stadium exteriors and large public squares.

These sites face direct rain, dust, strong wind, UV, and sometimes snow or salt air, depending on the region.

Outdoor performance requirements: brightness in sunlight, IP65 waterproof rating and wind resistance

Here the numbers must be taken seriously:

Brightness: for north‑facing façades or shaded streets, 4,000–5,000 nits can be enough; for direct sun in hot climates, 6,000–7,000+ nits may be required for daylight visibility.

IP rating: at least IP65 at the front is standard for outdoor transparent screens, with rear protection IP54 or better depending on exposure.

Wind resistance: the open structure of transparent LED helps reduce wind load, but the frame and anchors must still be calculated based on local wind codes.

Industry data: many city guidelines in Asia now limit maximum brightness of outdoor LED to around 5,000–6,000 nits at night with automatic dimming, to reduce light pollution and driver distraction.

Outdoor products also need surge protection, anti‑corrosion treatments (anodizing, powder coating, stainless fixings) and carefully engineered cable routing.

Structural design for outdoor transparent LED: load, heat dissipation and safety standards

In outdoor projects, the steel and aluminum supporting the LED often cost as much as the LED itself. Key points:

- Structural calculation based on wind load, building height and local codes.

- Load transfer from LED frame to main structure without introducing stress on curtain wall glass.

- Drainage paths so water does not pool near power supplies.

- Heat dissipation strategy that avoids hotspots while keeping modules sealed.

Collaborating with façade and structural engineers early avoids redesign later. A manufacturer like Zhenmei Wisdom typically provides module weights, allowable spans and mounting details so the local engineering team can complete the structural design safely.

Side‑by‑Side Comparison: Indoor vs Semi‑Outdoor vs Outdoor Transparent LED

Brightness and visibility by environment: nit levels for indoor, semi‑outdoor and outdoor use

A simple comparison table helps sharpen decisions:

- Indoor: 800–2,000 nits for lobbies and shop windows in controlled light, with dimming down to 200–300 nits at night.

- Semi‑outdoor: 2,000–4,000 nits to fight glare and skylight; automatic sensors strongly recommended.

- Outdoor: 4,000–7,000+ nits for sunlit façades, with strict dimming at night.

Too many buyers focus on maximum brightness only. In practice, effective automatic brightness control over the full day is more important for both visibility and comfort.

Pixel pitch, transparency and image clarity: how environment affects your choices

Indoor: prioritize finer pixel pitch (3–6 mm) and higher transparency since viewers are close and see both content and interior merchandizing.

Semi‑outdoor: slightly larger pitch (6–10 mm) is acceptable due to longer viewing distance; transparency around 55–70% typically balances image density and structural strength.

Outdoor: pixel pitch 8–25 mm is common. At 50 m away, a 15 mm pitch looks continuous; ultra‑fine pitch is wasted. Lower transparency (40–60%) can be acceptable when the façade is mainly a media surface.

Expert view: for building façades, define a “primary viewing distance” and design pixel pitch from that, instead of copying a neighbor’s specification; the same 10 mm pixel pitch behaves very differently on a 20 m vs 80 m wide façade.

Protection, lifespan and warranty differences between the three categories

Indoor transparent LED can reasonably expect 7–10 years of service with routine maintenance. Semi‑outdoor and outdoor systems endure harsher conditions and often have shorter nominal lifespans or stricter de‑rating in hot climates.

Warranty terms often reflect this:

- Indoor: 2–3 years standard, with options for 5 years.

- Semi‑outdoor: often 2–3 years with specific environmental limits.

- Outdoor: 2–5 years, but with more conditions on installation quality and operating hours.

When evaluating prices, it’s worth calculating cost per year of warranty‑backed operation, not just cost per square meter.

Engineering Deep Dive: IP Ratings, Materials and Thermal Management

IP ratings explained: what IP20, IP54 and IP65 mean for transparent LED displays

IP ratings describe protection against solids (first digit) and liquids (second digit):

- IP20: basic indoor protection against fingers and medium particle size, no water protection.

- IP54: limited dust ingress and protection against splashing water from any direction.

- IP65: dust‑tight and protection against low‑pressure water jets from all directions.

Transparent LED displays for true outdoor use should be at least IP65 front‑side; anything lower should be considered semi‑outdoor or architectural feature with additional structural protection.

A common pitfall: an IP65 LED module mounted into a poorly sealed frame is no longer an IP65 system. The whole assembly must be assessed.

Materials and sealing methods for outdoor transparent LED modules and power supplies

Outdoor transparent LED modules typically use:

- UV‑resistant plastics for clip parts or housings.

- Anodized aluminum profiles for frames and slats.

- Silicone gaskets and sealants at joints and cable entries.

- Conformal coating on PCBs to resist moisture and pollutants.

Power supplies may be IP67‑rated units mounted on the rear of the frame or installed in separate, more accessible technical spaces with sealed feed‑throughs.

Heat management, power consumption and their impact on stability and lifetime

Heat is the silent killer of LED systems. Power consumption scales roughly with brightness and LED density, and in outdoor conditions the sun adds to the thermal load.

Key engineering practices include:

- Using lower‑power LED packages with efficient optics.

- Designing open structures that allow convection without compromising IP.

- Implementing brightness scheduling and ambient‑light‑based dimming.

Engineering advice: aim to run the screen at 30–60% of its maximum brightness during most operating hours; this gives headroom for special events, reduces energy costs and extends LED lifetime significantly.

Cost, ROI and Total Lifecycle: Indoor vs Outdoor Transparent LED Investment

Cost components: hardware, structure, control system, installation and maintenance

For B2B buyers, transparent LED cost is more than the square‑meter price:

- LED modules and frames.

- Supporting steel or aluminum structure and glass integration.

- Control system, network, power distribution and surge protection.

- Installation (often a large portion of total cost for high façades).

- Ongoing maintenance, cleaning, access equipment and spares.

Outdoor projects usually show the highest ratio of structure and installation to LED cost, while indoor projects lean more on hardware and content production budgets.

Energy consumption, advertising impact and payback period in different environments

Energy use scales with brightness and operating hours. A 50 m² outdoor transparent screen at 5,000 nits can draw a few kilowatts when running at full power; indoor screens run at a fraction of that.

Industry observation: many retail clients see payback in 1–3 years when replacing printed campaigns with dynamic transparent LED, provided content is refreshed regularly and aligned with promotions.

Semi‑outdoor and outdoor façades often target brand value, tenant attraction or media revenue. In these cases, ROI should factor in rental income, higher occupancy or improved footfall, not just direct sales.

When outdoor transparent LED is worth the premium over indoor or traditional LED

Outdoor transparent LED justifies its higher cost in several scenarios:

- When preserving natural light and interior view is critical, such as office towers or mixed‑use façades.

- When city regulations restrict solid LED walls but allow transparent media façades.

- When structural constraints favor lightweight, wind‑permeable surfaces.

Traditional LED walls still make sense for pure advertising boards with no transparency requirement. Transparent LED is strongest where architecture and media must coexist.

How to Choose the Right Transparent LED Screen for Your Project

Step‑by‑step selection framework: from project goals to detailed specifications

A practical framework many project teams follow:

1) Clarify project goals: branding, sales promotion, tenant attraction, public information.

2) Define environment: indoor, semi‑outdoor or outdoor based on exposure, not just location.

3) Identify primary viewing distances and angles.

4) Set brightness, pixel pitch and transparency targets.

5) Define IP rating, temperature range and structural constraints.

6) Check compliance needs (local codes, fire, EMC).

7) Shortlist manufacturers with relevant reference projects.

Once you have this, comparing offers becomes a technical evaluation instead of a price lottery.

Checklist for B2B buyers: brightness, pixel pitch, IP rating, certifications and after‑sales

A concise checklist to run through during procurement:

- Brightness range and automatic dimming capability.

- Pixel pitch and recommended minimum viewing distance.

- Transparency percentage and impact on interior daylight.

- IP rating front and back, test reports if available.

- Operating temperature and humidity range.

- Structural and mounting details, weight per square meter.

- Certifications (CE, UL, EMC, safety) relevant to your market.

- After‑sales support, spare parts strategy and response times.

You can also ask for existing series details; for example, a holographic or crystal film screen such as Zhenmei Wisdom’s M‑series may suit specific indoor glass applications where ultra‑lightweight integration is key.

Common configuration templates for retail, corporate, transportation and architectural projects

Some typical starting points:

Retail storefront: indoor transparent, 1,200–2,000 nits, 3.9–7.8 mm pixel pitch, 65–85% transparency.

Corporate lobby: indoor transparent, 800–1,500 nits, 3–6 mm pitch, 60–80% transparency, focus on color accuracy.

Transport hub concourse: semi‑outdoor, 2,500–4,000 nits, 6–10 mm pitch, IP54 with high reliability.

Media façade: outdoor transparent, 4,000–7,000 nits, 10–25 mm pitch, IP65 front, engineered steel support.

These templates are not rules, but they offer a solid starting point for discussions with suppliers and designers.

Common Misconceptions, Risks and Compliance Issues

Misconceptions about using indoor transparent LED outdoors or in windows with strong sunlight

Common misconception 1: “The screen is behind glass, so it’s indoor.” If the glass gets hot, condenses moisture or receives strong sun, the modules face stress closer to semi‑outdoor conditions.

Common misconception 2: “Higher resolution is always better.” For long‑distance viewing and daytime brightness, you are paying for pixels people cannot see while limiting transparency and increasing power.

Hidden risks: condensation, corrosion, power safety and glass integration failures

Beyond obvious water ingress, several hidden risks can cause premature failures:

- Condensation inside modules or boxes due to temperature swings.

- Corrosion of connectors and fasteners in coastal or polluted environments.

- Poorly routed power and data cables creating trip hazards or weak points.

- Glass breakage risks if loads are transferred incorrectly through brackets.

Risk‑mitigation tip: insist on a mock‑up and site visit before finalizing the structural and cabling method; many integration problems are easier to see on a 2–3 module trial than on drawings.

Regulatory and safety considerations: local building codes, fire protection and wind load requirements

Outdoor and semi‑outdoor transparent LED installations must respect:

- Building codes related to façade modifications and added wind load.

- Fire safety requirements, including cable types and access routes.

- Electrical safety and grounding standards.

- In some cities, content brightness, operating hours and advertising regulations.

Ignoring these early can force redesigns or even removal after inspection, which is far more expensive than proper planning.

Operation, Maintenance and Long‑Term Performance Optimization

Routine inspection and cleaning strategies for indoor and outdoor transparent LED screens

Transparent LED screens are relatively easy to keep clean compared with solid cabinets, but dust and pollution still accumulate on slats and glass:

Indoor: periodic dry wiping or gentle cleaning on the glass side; inspect power supplies and cables once or twice a year.

Semi‑outdoor and outdoor: scheduled inspections for loose fixings, corrosion, gasket condition and module alignment, plus cleaning to maintain brightness and clarity.

Maintenance guideline: treat a large transparent façade like a piece of glass architecture with electronics; plan access routes, safety anchors and cleaning contracts from day one.

Preventive maintenance to extend screen life in semi‑outdoor and outdoor conditions

Preventive actions include:

- Checking temperature of power supplies and critical modules under full load.

- Verifying drainage and ensuring no standing water near electronics.

- Replacing suspect connectors or weathered cables before failure.

- Updating firmware carefully to maintain compatibility and stability.

Transparent systems with good preventive maintenance often outlast their planned media contracts, giving owners flexibility for re‑use.

Content and brightness management to balance visual impact, energy use and panel lifespan

Good content design is an underrated part of technical performance. High‑contrast but not over‑bright visuals, optimized for the specific grid structure, can look better than white‑heavy content at maximum brightness.

Ambient‑light sensors and scheduled dimming profiles help balance:

- Night‑time comfort for neighbors and occupants.

- Energy consumption and cooling loads.

- LED and power supply lifetime.

Industry Case Snapshots: Choosing Different Transparent LED Types by Scenario

Retail and luxury storefronts: when indoor transparent glass screens are sufficient

A typical high‑street fashion brand with a north‑facing street in a temperate city can often use indoor transparent LED behind the glass:

- 1,500 nits brightness, 4–6 mm pixel pitch.

- High transparency to keep the store visible and inviting.

- Seasonal campaigns pushed dynamically without re‑printing lightboxes.

Because sunlight and weather are mild, full outdoor engineering would be overkill and hurt ROI.

Transport hubs and public buildings: semi‑outdoor and outdoor façade solutions

In a metro station concourse open to the street, semi‑outdoor transparent LED along the glazing line can provide wayfinding and advertising:

- 3,000–4,000 nits, IP54, robust electronics with good cable protection.

- Structural design coordinated with station engineers for emergency access.

On the exterior of a new terminal or stadium, outdoor transparent LED with IP65 and wind‑engineered framing becomes a feature of the architecture, visible from long distances and designed for 24/7 operation.

Creative media façades and large buildings: outdoor high‑brightness transparent LED applications

For large office towers or mixed‑use developments, transparent LED can transform the whole façade into a programmable canvas:

- Pixel pitch 15–25 mm to balance cost and content resolution.

- 5,000–7,000 nits brightness with strict dimming curves.

- Structural frames that respect glass, insulation and maintenance access.

Here, the choice of outdoor transparent vs solid LED often comes down to internal daylight needs and planning rules; transparent solutions are increasingly favored where occupants want to keep views and natural light.

Indoor, Semi‑Outdoor and Outdoor Transparent LED Screens Answered

Can transparent LED screens be used outdoors all year round?

Yes, if they are designed as outdoor systems with IP65 or higher front protection, proper drainage, surge protection and a structure engineered for local wind and temperature conditions. Indoor products, even behind glass, are not equivalent.

What pixel pitch is best for transparent LED in shop windows or glass facades?

For shop windows with pedestrians 3–10 meters away, 3.9–7.8 mm pitch is common. For large façades viewed from tens of meters away, pitches from 10–25 mm are more economical and visually sufficient.

Do transparent LED displays block daylight or affect indoor comfort?

They do reduce daylight to some degree, depending on transparency, but typically far less than traditional LED walls. A 60–80% transparency screen still allows substantial light; detailed simulation or a small on‑site mock‑up helps evaluate the impact.

Are outdoor transparent LED screens always more expensive and how do they compare to traditional LED walls?

Outdoor transparent LED is usually more expensive per square meter than indoor transparent LED, and can be similar or sometimes higher than traditional outdoor LED once structure is included. However, transparent systems may reduce façade modifications, preserve daylight and comply more easily with planning rules, which can offset cost over the project lifecycle.

Conclusion

Indoor, semi‑outdoor and outdoor transparent LED screens are not three marketing labels, but three distinct engineering responses to environment, brightness and structural demands. Matching your project to the right category starts with defining exposure and viewing conditions, then specifying brightness, pixel pitch, transparency and IP rating based on real use, not just catalog numbers. From there, selecting a manufacturer with experience across glass integration, electronics and structural design turns a nice concept image into a reliable long‑term asset. If you approach transparent LED as part of the building system rather than a loose display, you can achieve both striking visuals and stable ROI.

References

- Samsung Insights – Indoor vs. outdoor LED: What are the differentiators?

- IEC 60529 – Degrees of protection provided by enclosures (IP Code).

- Various manufacturer datasheets for transparent LED screens (indoor, semi‑outdoor and outdoor series).